3D printing technology wave of the future

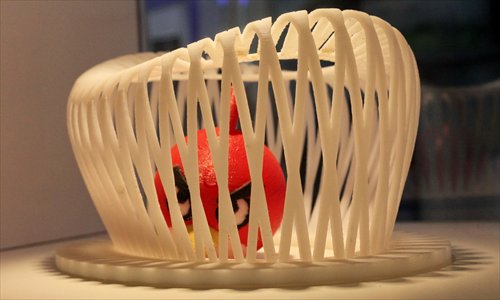

A decorative paperweight made from 3D printing technology. Photo: CFP

As the non-tech savvy struggle to swim in the vast sea of digital information out there, a Beijing-based trade body is busy diving ahead - hoping to popularize the mind-boggling 3D printing technology, which works by transforming 3D digital information into physical objects.

3D printing will not only play a "very positive role" in upgrading Chinese manufacturing, but also help bring small-scale manufacturing out of factories and into homes, hospitals, and schools, said Luo Jun, CEO of the Asian Manufacturing Association, at the 2013 World 3D Printing Technology Industry Conference in Beijing last month.

The technology is taking off in other areas, too. The recent box office-hit Iron Man 3 put 3D printing into action - and was perhaps best displayed by Iron Man's impressive 3D-printed suit.

A cutting-edge 3D printer can build up a real-world object from a computer-created digital model by laying down layers of liquid, powder or cell tissue. It will be able to make almost everything, from bread to clothes, and from simple chess pieces to more complicated airplanes, Hod Lipson, an associate professor of Cornell University, wrote in his book titled Fabricated: The New World of 3D Printing.

Lipson's research group has been painstakingly working on food printers since 2010, in hopes that people's health and metabolic data can be calculated by the machine to print out tailored meals for individual nutrition needs.

Lipson predicts 3D printing to eventually help humans master the physical world so that ordinary people can print complex tools at home, which will create huge changes for traditional manufacturing industries - and even possibly lead the global supply chain to be replaced by flexible small-scale manufacturers.

By that time, related professions are likely to be cast aside by this revolutionary technology, yet as intellectual property laws become invalid, the turn will balance the shift somewhat by fostering new jobs and opportunities for other markets, said Lipson.

A digital revolution?

Plugging a 3D printer into digital technology can not only copy existing objects but also create new ones.

With this feature, 3D printing is highly likely to push the third industrial revolution, namely a digital revolution - spurring change from mechanical and electronic production technologies to ones digital in nature, Xu Zhilei, a Chinese Academy of Engineering professor, said at the conference.

But other industrial experts think it's too early to jump to such conclusions.

Terry Wohlers, president of the US 3D printing research firm Wohlers Associates, expressed his concern about the unclear prospect of 3D printing at the conference, saying that, "We are not sure whether this technology is going to expand the limits of people's life like what the Internet is doing."

After all, as Shi Yusheng, vice director of China 3D Printing Technology Industry Alliance, pointed out at the press event, the technology still remains in the research phase and it is likely to take at least another 20 years for day-to-day uses to be realized.

But that doesn't mean 3D hasn't come a far way already. Over the past 30 years, the technology has been applied to aerospace, automotive and biomedical industries, producing highly complex designs that are too difficult for traditional techniques, said Luo.

Compared to traditional techniques, which rely on subtracting or cutting materials, 3D printing is an additive manufacturing process and only contributes what is needed - making 3D-printed mechanical parts lighter while reducing costly fuel consumption.

Luo noted that, however, 3D printing is not the best choice when it comes to mass production as it is more suitable for production in smaller batches, particularly for industrial designs.

Yet for all the skepticism, Chinese and foreign governments still have great expectations for 3D printing.

US President Obama said in February that 3D printing will play a positive role in boosting the US economy and asked Congress to "guarantee that the next revolution in manufacturing is made in America."

"We plan to establish a 3D printing research center, to revolutionize the way we produce as quickly as possible and cut increasing labor costs in the sector," Li Chuanheng, director of Economic and Information Technology Committee in Weifang, East China's Shandong Province, told the Global Times.

Obstacles ahead

3D printing has aroused major social appeal but will suffer from a flat market for some time, and thus, companies should not rush to the field, said Shi.

Manufacturers are hesitant to purchase 3D printers due to low-efficiency concerns, Zheng Lianming, sales manager of Nanjing Baoyan Automation Co, told the Global Times.

For instance, the printing of a door handle for an airplane may average 40 hours, much longer than one coming from a mature production line, he said.

Apart from the technology issue, the high selling price of the machines will be another hindrance to the popularity of industrial 3D printing, noted Zheng.

An imported industrial 3D printer from the UK sells for a steep $1 million, which can only be afforded by a government-supported research center, Luo Zheng, sales manager of global 3D printing company Renishaw (Shanghai) Trading Co, told the Global Times.

This means that the 3D printing business lies more with the services offered as opposed to the machines sold. But, it's hard to turn profits from such services due to the high costs of materials involved, Zheng said.

The company has to use more expensive imported "inks" as domestic ones are not yet ready for industrial 3D printing, he said. Given this obstacle, domestic companies are now starting to expand into personal 3D printing, which can make use of lower-quality materials unlike industrial printing.

"We are scheduled to sell 3D printers to DIY-conscious US families in late June, and anticipate satisfactory sales due to our competitive price edge over our foreign peers," he noted.

3D printers produced by Zheng's company are priced at around 50,000 yuan ($8,150) each, while the prices of same products from foreign companies can be several times higher.

However, the cheaper price tag does not ensure a large number of sales.

Products constructed by domestic 3D printers tend to be poorer in quality and lower in precision than those made by foreign machines. Additionally, because domestic companies fail to pay enough attention to software development for 3D printers, consumers may not prefer Chinese machines, said Zhang Chonghao, general engineering of Jiangsu Hehao Laser Tech.

But Zhang said that it's not time for foreign firms to count their chickens yet either, as they, too, have a long way to go yet in developing a mature method, which will be able to commercialize the new technology.