Chinese plants go 'smart' to turn manufacturing tide

By Xie Jun Source: Global Times Published: 2020/9/17 0:01:56

Chinese tech giant Alibaba on Wednesday unveiled a digital clothing manufacturing plant named "Xunxi Digital Factory" as part of its smart manufacturing business initiative.

For a long time, China has been searching for a solution to the challenge faced by its manufacturing industry, which is that many of its comparative advantages such as low labor costs and high productivity levels are being lost to other emerging markets like Vietnam and Cambodia. Now, a solution might be taking shape in the form of "smart" manufacturing plants.

It's not an easy road, as many Chinese manufacturers have been immersed in the labor-intensive production model for decades, and they don't have the money or manpower to upgrade their factories. But now, the participation of China's Internet giants, like Alibaba, is making it happen.

Rise of smart factories in China

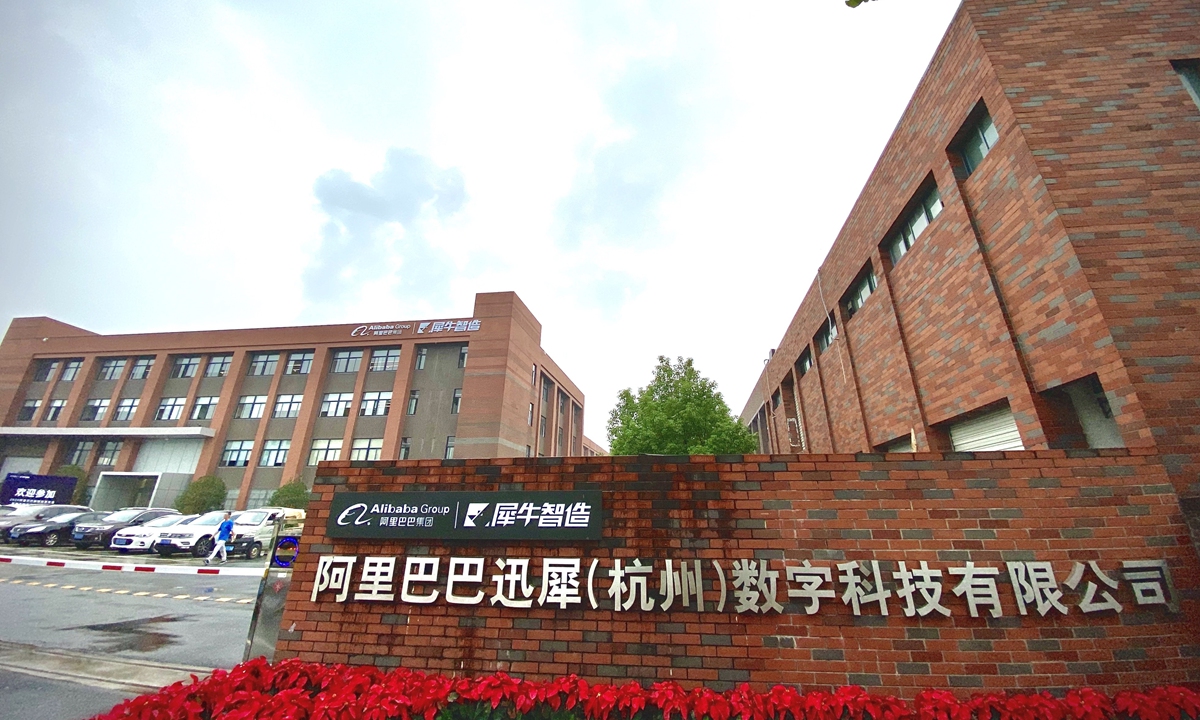

On Wednesday, Alibaba unveiled a digital clothing manufacturing plant named Xunxi Digital Factory as part of its smart manufacturing business initiative.

The plant, located in Hangzhou, East China's Zhejiang Province, does not look as futuristic as the ones in science fiction movies. Clothing machines are rolling, and laborers are busy at their work tables.

However, the factory's hardware, from sewing to printing machines, is connected to centralized cloud computing, which not only makes orders for production specifications but also records employee productivity.

Besides, the factory's embedded technologies, including cloud computing, artificial intelligence (AI) and the Internet of Things (loT), makes it possible for the factory to anticipate consumer needs, while also being able to complete small-size orders in a very short period of time, thus catering to the needs of the numerous small and medium-size companies in the country.

Chinese tech giant Alibaba on Wednesday unveiled a digital clothing manufacturing plant named "Xunxi Digital Factory" as part of its smart manufacturing business initiative.

Because of the factory's digitalized manufacturing supply chain that allows for fully customized production, the factory shortens delivery time by 75 percent and reduces the need to hold inventory by 30 percent, according to data provided by Alibaba to the Global Times.

The Xunxi factory is one example of China's attempts to build intelligent, high tech factories that provide alternatives to its traditional labor-intensive manufacturing plants. Recently, the World Economic Forum included four Chinese intelligent factories, including Xunxi, into its Global Lighthouse Network, a group of advanced manufacturing facilities that are applying the technologies of the Fourth Industrial Revolution.

Chinese air-conditioner maker Midea Group's plant in Guangzhou has also been included in the network for its use of high technologies that improve labor efficiency by nearly 30 percent and reduce unit costs to a great extent.

Chinese tech giant Alibaba on Wednesday unveiled a digital clothing manufacturing plant named "Xunxi Digital Factory" as part of its smart manufacturing business initiative.

Way to solve manufacturing bottleneck

China's traditional labor-intensive manufacturing model, made possible by the country's massive population base, has helped China develop into the world's factory as it churns out cheaply priced products for overseas countries.

But China can not count on that model any longer. For one thing, the younger generations in the country are no longer willing to accept low-paid repetitive work. Also, other emerging markets are providing new sources of cheap labor and low-end mass production, such as Vietnam.

As a result, many factories in China are already moving to neighboring countries to take advantage of labor costs that are even lower than China's. The situation is also complicated by political tensions between China and the US that have resulted in higher tariffs. The coronavirus pandemic has also affected global demand.

In the first eight months this year, China's exports slumped by 2.3 percent on a yearly basis to $1.57 trillion, customs data showed.

China has been looking for ways to break the bottleneck, including using high technologies to enhance product quality and increase efficiency. Will intelligent factories be the right answer? Industry magnates and experts are betting on it.

Wu Xuegang, CEO of Xunxi, said that China has not offered other advantages except for low manufacturing costs, and some global apparel giants have been reducing the proportion of China-made products in their overall product sourcing as they can source even cheaper products elsewhere.

However, he argued that global companies are not just looking at procurement costs when deciding on manufacturing arrangements.

"Compared with commodity costs, the cost of inventory is often more burdensome for companies. If China could use technologies to mass produce goods in a personalized, customized way (which reduces inventory waste), it would create a huge advantage in the global manufacturing competition," he told the Global Times on Tuesday.

Hu Qimu, a research fellow at the China Enterprise Confederation, said that many overseas countries have transferred manufacturing bases to emerging markets as they couldn't find other ways to reduce their overall costs apart from cutting salaries.

"However, China is in a period when it can use technologies and AI to transform the manufacturing industry so that the manufacturing shift might slow down or even stop, despite the increase in labor costs and overcapacity," he told the Global Times.

He also said that technology-backed, demand-driven production could be applied to heavy manufacturing industries like steel, though it's better to test the water with light manufacturing like cloth making, where customers are increasingly looking for personalized products.

However, intelligent manufacturing expert Guo Chaohui also pointed out some challenges faced by intelligent plants in China, such as inadequate automation levels and a potential obsession with showing off technological prowess. He also suggested that a model should be established in which smart factories can constantly improve their manufacturing, including details like quality, productivity and equipment stability.