HOME >> METRO SHANGHAI

3D-printing studio replicates the deceased

Source:Global Times Published: 2016-5-9 16:08:01

Funeral cosmetology aided by tech

An 81-year-old man surnamed Huang died in a traffic accident last month, resulting in severe damage to his head. However, thanks to the 3D-printing repair technology provided by Shanghai Funeral & Interment Service Center, Huang's face was perfectly restored before the funeral ceremony.

It was the first case finished by the body restoration studio at Shanghai Longhua Funeral Parlor. Set up at the end of March, the 3D Print Body Repair Studio is composed of eight members, including a senior engineer, a data modeler and several experts in the field of body restoration.

"Although 3D printing originated in the US, as far as I know, there is no report about applying this technology in funeral cosmetology so far," said Wang Gang, a country-level funeral cosmetologist and a member of the studio.

The studio can do partial restorations, such as only an eye or nose, as well as complete restoration, for example, of a whole head. It also offers skeletal restoration.

95 percent similar

According to Wang, 3D printing has two big advantages: high accuracy and high speed. "Once the model has been built through the software, the following printing process can be automated, because several machines can work simultaneously." Wang said, "It is especially efficient regarding natural disasters or emergencies with a high death toll."

It takes about two days for scanning and computer modeling, and after a half-day printing, an integral head can be finished. The end product is true to life, including pores and veins, reaching 95 percent similarity with the deceased's original appearance, according to the studio. In consideration of Chinese customs, restoration usually needs to be finished in three days.

One of the studio staff said the printer used for finished body parts is an imported, industrial-sized machine worth several million yuan, and is maintained off-site. The 3D printer at the studio is used for prototypes.

Wang told the Global Times that the traditional method of funeral cosmetology mostly uses wax; the process is time-consuming, and the end product has a comparatively low degree of similarity. In contrast, he said, 3D printing relies less on human labor, so it is more cost-effective.

Wang did not give specifics for client fees. "It varies according to the areas required to be printed, so it's hard to give an accurate number. But it won't be higher than the traditional method, which costs roughly 50,000 yuan ($7,692.31) on average for each body."

Putting into practice

Wang said he has followed 3D printing since 2008, when he and his colleagues had often thought about whether it could be applied to restorative procedures. The explosion in Tianjin motivated them to put the idea into practice.

"We went there to assist, restoring only 10 bodies in more than 20 days, but over 100 people died in the accident," Wang said, "We really wanted to restore every single body so that they can die with peace and dignity. Sadly, we failed."

The accident was a critical turning point for the establishment of the studio. After the team came back, Wang said, he and other experts studied relevant cases and floated the idea of 3D printing. "We had discussed the potential since last October, demonstrating the possibility over and over, until this March when we officially set up," said Wang.

After considering several materials for printing, the studio chose mixed gypsum. "Because the repaired part will be cremated together with the remains afterwards, the material should be easier to decompose than bones at a high temperature. More importantly, it must be non-toxic," Wang said.

The most difficult part

In general, 3D printing is machine-dependent, but humans still do the preliminary work, like building the model. Through software like 3D Max and ZBrush, data modelers need to transform the two-dimensional image into a 3D model based on photos provided by families.

"I would say the most important and difficult part is to gather materials, because the pictures they gave are not clear enough," said Wang, "What's more, time and age are big problems. Many old people haven't taken any photos in the recent 10 years, so the appearance in the picture differs a lot from the time when they passed away."

Therefore, at each step the team has to regularly communicate with the families, checking details like whether the person had high cheekbones or a characteristic nose. Even after the product is printed, there still could be tiny color differences, entailing consultation with the families and edits.

Wang's WeChat history contains conversations with families. Wang sends them short videos of the modeling process from front and side angles.

The studio is now working on two more cases. Wang said the families are satisfied so far, and the studio is also researching and analyzing public reception and awareness.

"We hope to develop our modeling to a mature level," Wang said. "We are now also considering building a database and dividing people into different genders and ages. Then through digital identification and comparison, the modeling process can be automated. "

Wang estimated that it would take two to three years to build the database, before which over 80,000 people's data would be collected.

3D printing originated in the US, with commercial printers first taking off just before the turn of the century. Today, people are paying closer attention to the technology and the opportunities it offers.

"This morning the Russia Funeral Association came for a visit." said Wang, "They are curious about our studio and even asked if there is any possibility that we two could exchange talents and skills."

The article was written by Qu Xinyi

It was the first case finished by the body restoration studio at Shanghai Longhua Funeral Parlor. Set up at the end of March, the 3D Print Body Repair Studio is composed of eight members, including a senior engineer, a data modeler and several experts in the field of body restoration.

"Although 3D printing originated in the US, as far as I know, there is no report about applying this technology in funeral cosmetology so far," said Wang Gang, a country-level funeral cosmetologist and a member of the studio.

Wang Gang holds a printed face. Photo: CFP

The studio can do partial restorations, such as only an eye or nose, as well as complete restoration, for example, of a whole head. It also offers skeletal restoration.

95 percent similar

According to Wang, 3D printing has two big advantages: high accuracy and high speed. "Once the model has been built through the software, the following printing process can be automated, because several machines can work simultaneously." Wang said, "It is especially efficient regarding natural disasters or emergencies with a high death toll."

It takes about two days for scanning and computer modeling, and after a half-day printing, an integral head can be finished. The end product is true to life, including pores and veins, reaching 95 percent similarity with the deceased's original appearance, according to the studio. In consideration of Chinese customs, restoration usually needs to be finished in three days.

One of the studio staff said the printer used for finished body parts is an imported, industrial-sized machine worth several million yuan, and is maintained off-site. The 3D printer at the studio is used for prototypes.

Wang told the Global Times that the traditional method of funeral cosmetology mostly uses wax; the process is time-consuming, and the end product has a comparatively low degree of similarity. In contrast, he said, 3D printing relies less on human labor, so it is more cost-effective.

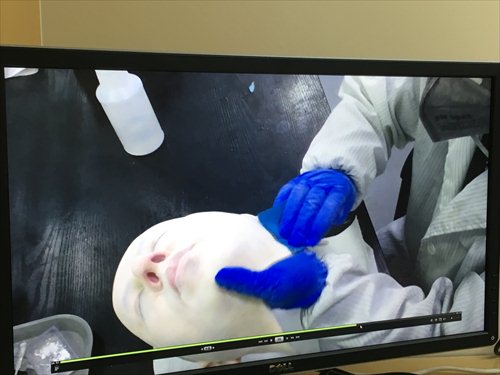

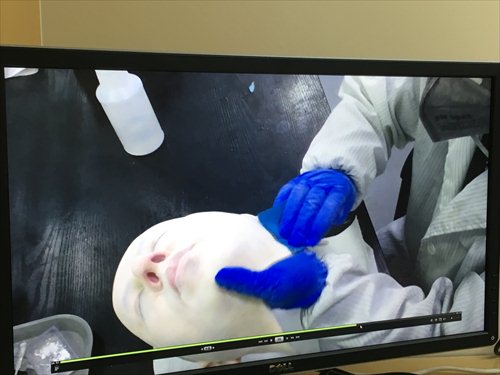

A technician removes waste from a 3D-printed face. Photo: Qu Xinyi/GT

Wang did not give specifics for client fees. "It varies according to the areas required to be printed, so it's hard to give an accurate number. But it won't be higher than the traditional method, which costs roughly 50,000 yuan ($7,692.31) on average for each body."

Putting into practice

Wang said he has followed 3D printing since 2008, when he and his colleagues had often thought about whether it could be applied to restorative procedures. The explosion in Tianjin motivated them to put the idea into practice.

"We went there to assist, restoring only 10 bodies in more than 20 days, but over 100 people died in the accident," Wang said, "We really wanted to restore every single body so that they can die with peace and dignity. Sadly, we failed."

The accident was a critical turning point for the establishment of the studio. After the team came back, Wang said, he and other experts studied relevant cases and floated the idea of 3D printing. "We had discussed the potential since last October, demonstrating the possibility over and over, until this March when we officially set up," said Wang.

After considering several materials for printing, the studio chose mixed gypsum. "Because the repaired part will be cremated together with the remains afterwards, the material should be easier to decompose than bones at a high temperature. More importantly, it must be non-toxic," Wang said.

The technician polishes the face. Photo: Qu Xinyi/GT

The most difficult part

In general, 3D printing is machine-dependent, but humans still do the preliminary work, like building the model. Through software like 3D Max and ZBrush, data modelers need to transform the two-dimensional image into a 3D model based on photos provided by families.

"I would say the most important and difficult part is to gather materials, because the pictures they gave are not clear enough," said Wang, "What's more, time and age are big problems. Many old people haven't taken any photos in the recent 10 years, so the appearance in the picture differs a lot from the time when they passed away."

Therefore, at each step the team has to regularly communicate with the families, checking details like whether the person had high cheekbones or a characteristic nose. Even after the product is printed, there still could be tiny color differences, entailing consultation with the families and edits.

The face is washed after printing. Photo: Qu Xinyi/GT

Wang's WeChat history contains conversations with families. Wang sends them short videos of the modeling process from front and side angles.

The studio is now working on two more cases. Wang said the families are satisfied so far, and the studio is also researching and analyzing public reception and awareness.

"We hope to develop our modeling to a mature level," Wang said. "We are now also considering building a database and dividing people into different genders and ages. Then through digital identification and comparison, the modeling process can be automated. "

Wang estimated that it would take two to three years to build the database, before which over 80,000 people's data would be collected.

3D printing originated in the US, with commercial printers first taking off just before the turn of the century. Today, people are paying closer attention to the technology and the opportunities it offers.

"This morning the Russia Funeral Association came for a visit." said Wang, "They are curious about our studio and even asked if there is any possibility that we two could exchange talents and skills."

Prototypes are displayed on table. Photo: Qu Xinyi/GT

The article was written by Qu Xinyi

Posted in: Metro Shanghai, City Panorama