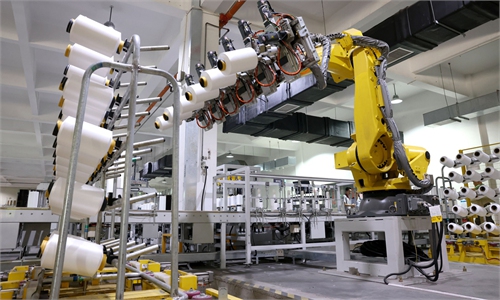

China's domestically developed embodied large robot model performs tasks in car factory, in key development

A general-purpose intelligent humanoid robot developed by Shenzhen-based AI2 Robotics works at an automotive factory. File photo: Courtesy of AI2 Robotics

A Shenzhen-based tech company's general-purpose intelligent humanoid robot, with a self-developed large model, has been deployed in an automotive factory, performing intelligent tasks across multiple scenarios, including quality inspection, assembly, logistics, and maintenance. This marks the first full-scenario validation of a domestically developed embodied large model in automotive manufacturing, the Global Times has learned.

The embodied robot, named AlphaBot2, was developed by Shenzhen-based AI² Robotics with its self-developed large model. The company has signed a strategic cooperation agreement with Chinese automaker Dongfeng Liuzhou Motor Co to conduct intelligent operations in factories, AI² Robotics said in a statement sent to the Global Times.

Boasting a battery life exceeding six hours, AlphaBot2 is well-equipped to handle extended work periods without interruption. Compared with traditional industrial robots, it has stronger scene generalization capabilities and higher levels of intelligent interaction, enabling it to operate any object and complete diverse tasks in any environment, said the company.

Guo Yandong, founder and CEO of AI² Robotics, said in the statement that AlphaBot2 will continuously feed real industrial data back to the company's self-developed embodied large model that endows the robot with exceptional spatial intelligence and learning capabilities.

"It will make our robots smarter and enable them to achieve breakthroughs in more challenging applications across a wider range of scenarios," Guo said. This process will enhance the large model's understanding of complex environments and task details while improving the robot's efficiency, precision, and stability through on-site learning.

According to media reports, this is also an example of the practice of embodied intelligence, where a large model serves as the artificial intelligence (AI) core, enabling the robot to perform intelligent tasks across an automotive factory.

The speed at which robots are being put on the job in manufacturing is accelerating across China. In recent years, Chinese robotics companies have accelerated their entry into industrial scenarios.

For example, Shenzhen-based Dobot Robotics announced that its industrial robots have completed some precision assembly processes on the production lines of Mercedes-Benz, BYD, Porsche and many other car brands, according to press releases from the company.

UBTECH has successfully conducted a collaborative practical training program for humanoid robots at carmaker ZEEKR's 5G intelligent factory. Leju Robotics announced that its Kuavo humanoid robots have been deployed in batches at the FAW Hongqi factory, according to media reports.

Experts see industrial manufacturing, commercial services and family companionship as the primary applications for embodied AI robots and humanoid robots. Among these functions, industrial manufacturing is poised to lead the way.

Zhong Xiangyun, a humanoid robot industry observer, told the Global Times on Monday that China's robust industrial base provides fertile ground for intelligent robot development. Deep integration into industrial manufacturing will significantly enhance their tool manipulation and task execution capabilities.

A recent industry report forecast that China's humanoid robot market will reach 8.24 billion yuan ($1.14 billion) this year, accounting for half of the global market. By 2030, the market could skyrocket to about 870 billion yuan, the Xinhua News Agency reported.

Previously disclosed plans from the Ministry of Industry and Information Technology show that China aims to establish a preliminary innovation system for humanoid robots this year, with plans to have a secure, reliable industrial and supply chain system by 2027, when related products will be deeply integrated into the real economy, per Xinhua.