SOURCE / PRESS RELEASE

Hi-MO X10 Lightweight Module Awarded the Grade AAA Certification from TÜV Rheinland

Against the backdrop of the accelerated popularization of distributed photovoltaics (PV) and the surging demand for the renovation of old factories, the BC technology route has brought another piece of good news. Recently, TÜV Rheinland Germany, an internationally authoritative testing and certification body, officially announced that Hi-MO X10 Lightweight Module has been awarded the Grade AAA certification under the 2PfG 2992/08.24 standard. This is not only the first BC product in the PV industry to obtain the highest-level certification under this standard, but also marks a major breakthrough for LONGi in the lightweight technology and reliability of PV modules, providing a more valuable product solution for distributed PV scenarios.

01- Authoritative Certification, Outstanding Performance

TÜV Rheinland’s 2PfG 2992/08.24 standard is specifically developed for lightweight PV modules, covering various innovative structures such as flexible, semi-rigid, and rigid types. Based on the severity of application scenarios, the standard sets three grades: Grade AAA, AA, and A. Among them, Grade AAA, as the highest level, is exclusively applicable to utility-scale projects with extremely high reliability requirements, which need to pass a series of extreme tests including thermal cycling, damp heat-freeze, PID (Potential Induced Degradation), wind uplift resistance, vibration resistance, and abrasion resistance.

With its excellent overall performance, the Hi-MO X10 Lightweight Module successfully passed all tests, demonstrating exceptional durability, safety, and reliability.

In China, over 30% of industrial and commercial rooftops cannot be equipped with PV systems due to insufficient load-bearing capacity. Based on this insight, LONGi launched the Hi-MO X10 Lightweight Module in May 2025. Specifically developed for low-load rooftop scenarios such as old factories, lightweight color steel tiles, and grid structures, this module builds differentiated competitiveness providing four core advantages: light weight, speed, safety, and profitability.

Lightweight – Innovative Weight Reduction

With a weight of only 7.2 kg/m², the module is 42% lighter than conventional modules, fundamentally solving the pain point of insufficient load-bearing capacity of old rooftops.

Fast – Efficient Installation

The installation of the Hi-MO X10 Lightweight Module does not require additional rooftop reinforcement, completely eliminating time-consuming and labor-intensive reinforcement work. Compared with traditional reinforcement solutions, a 1MW project can save up to 34 days of construction period; even compared with the adhesive installation method of other flexible modules, it can still save 10 days. Meanwhile, it adopts the conventional front-side (A-side) clamp installation, so the construction team does not need special tools or professional training, truly achieving smooth integration with existing processes.

Safe – Comprehensive Protection

Through the synergy of high-strength glass, thickened frames, laminated I-shaped reinforcing ribs, and a patented mortise-tenon frame connection structure, the module’s bending resistance, torsion resistance, and anti-crack performance have been significantly enhanced. Combined with the intelligent protection of the unique weak conduction design of HPBC 2.0 technology, it effectively reduces the hot spot temperature under shading – when a single cell is shaded, it can recover up to 70% of power loss. The thickened adhesive film further blocks moisture erosion, building a comprehensive and reliable protection system.

Profitable – Maximum Returns

It completely eliminates reinforcement costs, enabling a 1MW project to save up to 500,000 yuan in initial investment. With a mass-produced power output of up to 560W and an efficiency of 24.8%, its power generation density per unit area reaches 248W/m², reducing the BOS (Balance of System) cost per watt by approximately 33%. Equipped with a 15-year product material warranty and a 30-year power warranty, it ensures the long-term stable operation of the PV plant and sustained revenue.

02- Practical Verification, Demonstrating Strength

At the factory project of Hangzhou Shujie Sanitary Products Co., Ltd., the first national demonstration PV plant built with the Hi-MO X10 Lightweight Module has verified the product’s outstanding performance.

As a typical high-energy-consuming enterprise, Shujie’s factory relies heavily on continuous and stable power supply for raw material processing, product drying, and packaging. Conventional modules are limited by the rooftop’s load-bearing capacity and require high reinforcement costs, while the existing lightweight flexible modules on the market generally have pain points such as low power generation efficiency, material aging, and weak fire resistance.

With its light weight of 7.2 kg/m², the Hi-MO X10 Lightweight Module completely solved the "unbearable weight" of Shujie’s factory rooftop. This 1.5MW PV plant is expected to generate 1.6 million kWh of electricity annually, 85% of which can be directly consumed within the park. It can save over 800,000 yuan in electricity costs and gain nearly 100,000 yuan in additional revenue from electricity sales each year, truly realizing the upgrade to green energy without damaging the factory structure or suspending production operations.

It has been reported that a number of LONGi projects using the Hi-MO X10 Lightweight Module in various industry scenarios such as water utilities, chemical engineering, metallurgy, textiles, and electronics are currently under construction.

Facing the urgent demand for global energy transition, LONGi attaches great importance to independent innovation and technological R&D, and has always promoted cost reduction and efficiency improvement in the PV industry through the industrialization of advanced technologies. Over the past five years (2020-24), LONGi has invested over 26.8 billion yuan in R&D and holds 480 patents for BC cell modules. To address the diverse and complex customer needs in diverse scenarios, LONGi has successively launched distributed scenario-specific products such as the Hi-MO X10 anti-dust, anti-glare, and lightweight design and the high-end residential EcoLife series, leading the high-quality development of the industry through continuous technological breakthroughs.

Li Weichun (left), Vice President of Global Power Electronics Product Services of TüV Rheinland and Lü Yuan, President of Product and Solution Center from LONGi DGBG

01- Authoritative Certification, Outstanding Performance

TÜV Rheinland’s 2PfG 2992/08.24 standard is specifically developed for lightweight PV modules, covering various innovative structures such as flexible, semi-rigid, and rigid types. Based on the severity of application scenarios, the standard sets three grades: Grade AAA, AA, and A. Among them, Grade AAA, as the highest level, is exclusively applicable to utility-scale projects with extremely high reliability requirements, which need to pass a series of extreme tests including thermal cycling, damp heat-freeze, PID (Potential Induced Degradation), wind uplift resistance, vibration resistance, and abrasion resistance.

With its excellent overall performance, the Hi-MO X10 Lightweight Module successfully passed all tests, demonstrating exceptional durability, safety, and reliability.

In China, over 30% of industrial and commercial rooftops cannot be equipped with PV systems due to insufficient load-bearing capacity. Based on this insight, LONGi launched the Hi-MO X10 Lightweight Module in May 2025. Specifically developed for low-load rooftop scenarios such as old factories, lightweight color steel tiles, and grid structures, this module builds differentiated competitiveness providing four core advantages: light weight, speed, safety, and profitability.

Lightweight – Innovative Weight Reduction

With a weight of only 7.2 kg/m², the module is 42% lighter than conventional modules, fundamentally solving the pain point of insufficient load-bearing capacity of old rooftops.

Fast – Efficient Installation

The installation of the Hi-MO X10 Lightweight Module does not require additional rooftop reinforcement, completely eliminating time-consuming and labor-intensive reinforcement work. Compared with traditional reinforcement solutions, a 1MW project can save up to 34 days of construction period; even compared with the adhesive installation method of other flexible modules, it can still save 10 days. Meanwhile, it adopts the conventional front-side (A-side) clamp installation, so the construction team does not need special tools or professional training, truly achieving smooth integration with existing processes.

Safe – Comprehensive Protection

Through the synergy of high-strength glass, thickened frames, laminated I-shaped reinforcing ribs, and a patented mortise-tenon frame connection structure, the module’s bending resistance, torsion resistance, and anti-crack performance have been significantly enhanced. Combined with the intelligent protection of the unique weak conduction design of HPBC 2.0 technology, it effectively reduces the hot spot temperature under shading – when a single cell is shaded, it can recover up to 70% of power loss. The thickened adhesive film further blocks moisture erosion, building a comprehensive and reliable protection system.

Profitable – Maximum Returns

It completely eliminates reinforcement costs, enabling a 1MW project to save up to 500,000 yuan in initial investment. With a mass-produced power output of up to 560W and an efficiency of 24.8%, its power generation density per unit area reaches 248W/m², reducing the BOS (Balance of System) cost per watt by approximately 33%. Equipped with a 15-year product material warranty and a 30-year power warranty, it ensures the long-term stable operation of the PV plant and sustained revenue.

02- Practical Verification, Demonstrating Strength

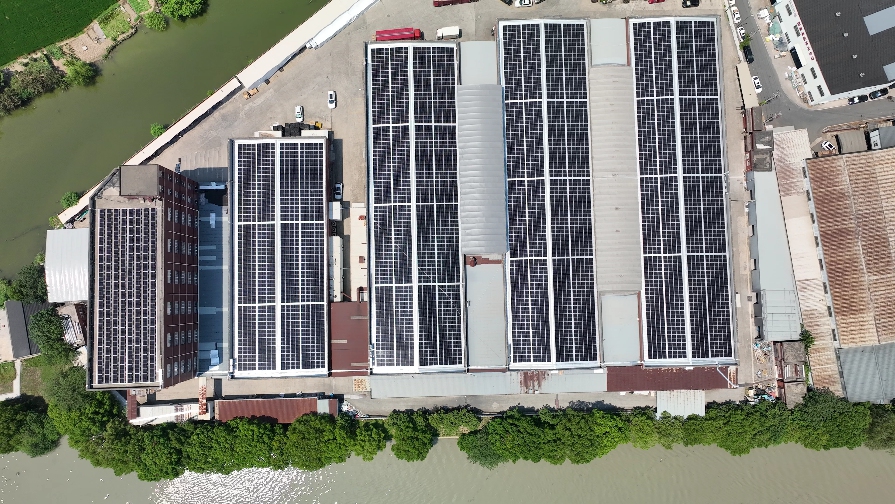

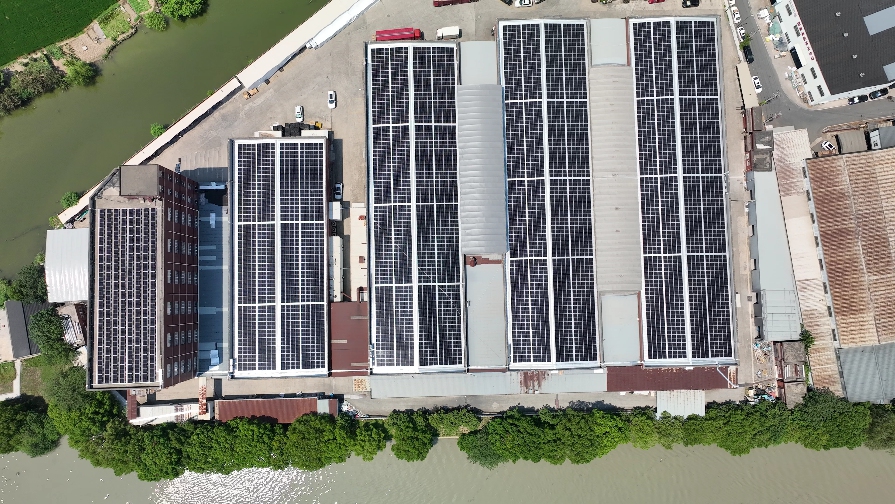

At the factory project of Hangzhou Shujie Sanitary Products Co., Ltd., the first national demonstration PV plant built with the Hi-MO X10 Lightweight Module has verified the product’s outstanding performance.

As a typical high-energy-consuming enterprise, Shujie’s factory relies heavily on continuous and stable power supply for raw material processing, product drying, and packaging. Conventional modules are limited by the rooftop’s load-bearing capacity and require high reinforcement costs, while the existing lightweight flexible modules on the market generally have pain points such as low power generation efficiency, material aging, and weak fire resistance.

With its light weight of 7.2 kg/m², the Hi-MO X10 Lightweight Module completely solved the "unbearable weight" of Shujie’s factory rooftop. This 1.5MW PV plant is expected to generate 1.6 million kWh of electricity annually, 85% of which can be directly consumed within the park. It can save over 800,000 yuan in electricity costs and gain nearly 100,000 yuan in additional revenue from electricity sales each year, truly realizing the upgrade to green energy without damaging the factory structure or suspending production operations.

The picture shows the PV project on the rooftop of Hangzhou Shujie Sanitary Products Co., Ltd.

It has been reported that a number of LONGi projects using the Hi-MO X10 Lightweight Module in various industry scenarios such as water utilities, chemical engineering, metallurgy, textiles, and electronics are currently under construction.

Facing the urgent demand for global energy transition, LONGi attaches great importance to independent innovation and technological R&D, and has always promoted cost reduction and efficiency improvement in the PV industry through the industrialization of advanced technologies. Over the past five years (2020-24), LONGi has invested over 26.8 billion yuan in R&D and holds 480 patents for BC cell modules. To address the diverse and complex customer needs in diverse scenarios, LONGi has successively launched distributed scenario-specific products such as the Hi-MO X10 anti-dust, anti-glare, and lightweight design and the high-end residential EcoLife series, leading the high-quality development of the industry through continuous technological breakthroughs.