HOME >> CHINA

Chinese firm uses robots for tunnel construction

By Xu Keyue in Fuquan Source:Global Times Published: 2019/9/19 22:45:23

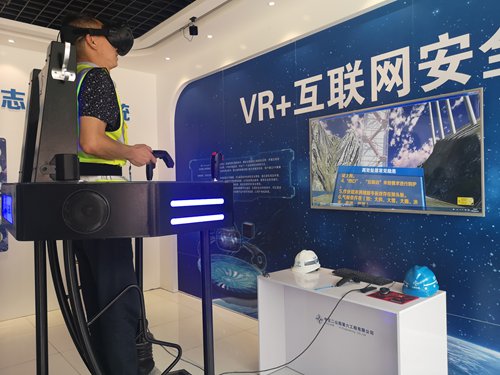

In the training room, Liu Guiping, the company's safety coordinator, takes the security training and experiences the safety incident in a simulated situation, based on virtual reality technology. Photo: Xu Keyue/GT

Longchang Tunnel, a part of Guihuang Expressway in Fuquan, Southwest China's Guizhou Province is two kilometers long and passes through a thick layer of limestone and dolomite. Photo: Xu Keyue/GT

A state-owned company is using advanced technology in the mechanical construction of a tunnel in the mountains in Southwest China's Guizhou Province, which saves manpower and ensures construction safety and quality.

Longchang Tunnel, a part of Guihuang Expressway in the city of Fuquan, is two kilometers long and passes through a thick layer of limestone and dolomite, which makes the construction difficult.

Challenged by the complex construction environment, China Communications Construction Second Highway Engineering Co has pioneered the use of robots and improved safety with the use of a real-time monitoring system and GPS. Virtual reality (VR) technology is also being used to train construction workers, Ma Jianyun, general engineer of the tunnel project, told the Global Times.

The tunnel construction is scheduled to be completed by the end of 2019, said Fan Wei, director of a department of the Party committee in the company. After construction, the tunnel will play an important role in regional industrialization and urbanization, and will help to lift surrounding towns and counties out of poverty.

VR pre-job training

Workers have to take security training before they join the construction. The training includes watching animated demonstrations of safety situations based on VR technology and playing assessment games to examine the workers' construction knowledge, the Global Times reporter saw on site.

In the training room, Liu Guiping, the company's safety coordinator, showed how to douse a fire using an extinguisher, along with other VR-simulated situations.

The innovative training greatly improves the effect and improves workers' awareness of safety, Liu said.

Robots at work

The company is using nine kinds of robotic machines on the project, each of which has a clear function, such as advanced geological forecasting, tunneling, and arched frame installation.

The "robot family," which replaces human tasks, is the main labor force in the construction, Ma noted.

Workers only need to sit in the air-conditioned cabin of the intelligent three-arm drilling jumbo to press the start button and watch the machine accurately locate and drill holes in the tunnel.

The 17-meter jumbo has telescopic drilling arms and can walk flexibly. The workers have named it "bumblebee," the project manager Chen Jiabao said.

"The traditional manual construction method requires nearly 20 people who have to endure dust, noise and sweat, and must take safety risks. The intelligent system now only needs two operators to control the robot, which makes the project faster, more efficient, and of higher quality and safety," Ma said.

As well as the drilling, other processes of the tunneling have their own robots.

"The mechanical construction in the whole process has saved manpower by 35 percent. The number of people needed for the drilling, arch frame installation and shotcrete processes was reduced from about 40 to 12," Ma said.

Intelligent monitor system ensures workers' safety

The company developed a Project Management System based on big data, GPS and AI technology, which can comprehensively monitor the tunnel, track workers, analyze air quality both inside and outside, and record the construction process.

"The system makes the whole construction traceable," Ma said.

Every worker has to wear a uniform that has a GPS chip inserted before entering the tunnel. And the workers can communicate and share moments with each other in the system on their mobile devices. The company can also respond immediately when emergencies occur, ensuring construction safety.

The system also can provide geological forecasts by using geology radar. In emergency situations, workers in the tunnel can call operators outside by using an emergency broadcasting system.

Tunneling incidents result in fatalities every year. According to media reports, three workers died and one was injured in August at the construction site for a tunnel in Zhaoqing, South China's Guangdong Province. And five workers died in May after the collapse of a subway tunnel that was being constructed in Qingdao, East China's Shandong Province.

RELATED ARTICLES:

Posted in: SOCIETY