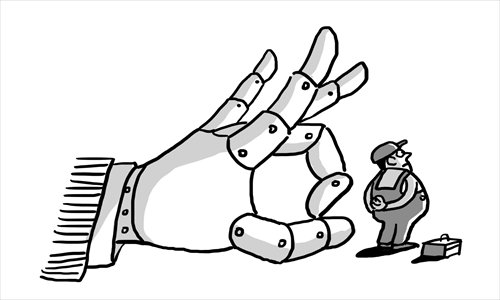

Factory workers offer no welcome to their robot masters

The annual International Toy Fair held in New York during the Chinese Lunar New Year was fun as usual.

Yes, it is a trade show. But it's my favorite one to visit, since the exhibitors basically turn the Jacob K. Javits Convention Center into a huge playground, and while many of the visitors may be adults wearing suits, their demeanor is more like that of giggling children.

But I came away fearful, frightened not by the giant animated stuffed animals who put their paws on my shoulders unexpectedly, or the remotely controlled fish balloons flying right above my head. The baby potty with an iPad stand is a little scary. But no, it's not that either.

I was frightened because I chatted with a dozen or so toy makers who are either based in China or have factories there, and all of them told me they either have just finished an "automation upgrade" or are planning to do so.

This, in plain English, means replacing humans with robots. At the end of last year when Foxconn, a major manufacturer of Apple products that employs 1 million workers in China, announced it would bring in 1 million robots in three years, it was shocking news. Now it seems that was only the beginning of an irreversible trend.

This is not a surprise, considering the rapidly rising labor costs in China.

Pay in manufacturing industry in China has been rising at a 20 percent pace annually in recent years. And China's 12th Five-Year Plan set a goal of doubling the minimum wage by 2020, meaning at least a 13 percent annual increase until then.

In addition, the awareness of labor rights among workers has also prompted employers to improve workers' benefits.

For example, Foxconn, after being haunted by a slew of suicides within its workforce, announced a series of new benefits packages to please its employees.

This already sent some manufacturers to cheaper Southeast Asian countries, and pushed foreign investment in China down by 3.7 percent last year. Others, like those I talked to, have decided to keep producing in China now for various reasons: A certain raw material they use is cheaper to purchase in China; their electronic products need skilled workers Vietnam or Myanmar cannot provide yet, or simply because they themselves are Chinese.

But they may have to fight a tougher battle for survival. As one toy maker from Ningbo, Zhejiang province, told me, upgrading machines is a hard decision because it costs money and drags down profits. But in the long run, it's the only way for the company to have a future.

The full effect of this may not have shown just yet. Many manufacturing hubs in China are still struggling with the seasonal labor shortage that usually occurs after the Lunar New Year when many mobile workers don't return. And the quickly aging population also sounds an alarm about the labor force for the near future.

But the looming invasion of robots to the assembly lines makes me wonder how long China's official unemployment rate of 4.1 percent can hold up.

The tide could turn quickly, as happened in the US.

As the Atlantic magazine pointed out in a cover story last year, jobs in the manufacturing industry in the US grew from the end of the Great Depression to the 1970s, stayed flat in the 1980s and 1990s and collapsed from 1999 to 2009 when one-third of jobs were wiped out.

The problem, as the joke points out, is that "A modern textile mill employs only a man and a dog. The man is there to feed the dog, and the dog is there to keep the man away from the machines."

The high-tech tsunami doesn't seem to be resistible anywhere in the world. For human beings who are likely to be destroyed by machines, there are two options.

We can wait till Skynet strikes and then start the resistance against the Terminators, or, more realistically, we can learn a lesson from the US and figure out a way to coexist well with the machines and one another.

Many experts in the US pointed out that although high tech improves productivity, an achievement that should benefit human society in a whole, the profits only go to the employers.

In other words, capitalism turns ordinary workers into drones who are losing any sense of power.

There are a lot of solutions, such as providing better training and education to workers, and adopting a more equal income distribution system.

None of this is easy to do. But we can get a jump on it now before the nightmare really starts.

The author is a New York-based journalist. rong_xiaoqing@ hotmail.com