China’s factories will keep running during the Spring Festival holidays, supplying medical gear, stay-at-home products to entire world

A villager steams red Ciba in Baiguo Village of Yuping Dong Autonomous County in Tongren City, southwest China's Guizhou Province, Jan. 15, 2021. It's a tradition for people here to make red Ciba, a traditional glutinous rice cake dyed with red food coloring, to prepare for the upcoming Chinese Spring Festival which falls on Feb. 12 this year.Photo:Xinhua

China's weeklong Spring Festival holidays are less than one month away. At this time last year, the coronavirus outbreak swept parts of the world's second-largest economy, grounding production with a shutdown rate nearing 90 percent. But now, the world's factory is roaring back, with 90 percent the rate at which production operates.

China's industrial machines are primed to meet soaring overseas demand, even for the upcoming Spring Festival holidays, during which factories traditionally shut down for a couple of weeks and exports waned.

This year, as the sporadic resurgence of coronavirus infection cases prompts more workers not to return to their hometowns and labor shortages are eased, the world will likely see Chinese factories heat up production, shipping everything from stay-at-home products, electronic components, toys and vaccines, to medical gear such as facial masks, which China had produced 40 units for every person around the world in 2020.

No other country could rival China in the global supply chain and the silver lining it has provided to the world's anti-epidemic effort.

The export boom would also mark a drastic turnaround from 2020, when foreign trade dove 6.4 percent in the first quarter as coronavirus halted economic activities. Analysts expect China's trade to bounce back more than 20 percent in the first three months and jump by more than 10 percent for the whole year.

A worker checks the quality of ordered masks at a mask factory in Huaibei, East China's Anhui Province, April 17, 2020. Photo: cnsphoto

Humming factories

At a toy-making factory in Dongguan, South China's Guangdong Province, more than 100 migrant workers have decided to stay in the city during the upcoming Spring Festival holidays, traditionally a time for people to go home for family reunions.

The factory, which employs about 800 workers, most of whom are not locals, issued a new policy on Monday, giving migrant workers who would stay 1,000 yuan to 2,000 yuan, in addition to overtime pay.

The policy echoes calls from a number of local governments in recent days, including first-tier cities like Beijing and Shanghai as well as manufacturing bases like Dongguan and adjacent Foshan, to encourage employees to stay to reduce mobility against the backdrop of reported sporadic coronavirus cases.

For instance, Foshan said it will release consumption coupons worth millions of yuan and free entrance to all local top-level tourism spots as stay-in-Foshan benefits.

East China's Yiwu, also known as the world's supermarket, said it will organize different New Year events, such as making dumplings or New Year parties for those who choose to stay. The city also set up volunteer teams and Chinese and English hotlines for foreigners who need help during the weeklong holidays.

"In the past, operations at the factory were suspended for more than two weeks during the Spring Festival break. And we generally face a labor shortage issue afterward. But as more workers stay this year, we're able to resume production very quickly after the holidays," Zhai Suoling, the factory's manager, told the Global Times on Tuesday.

Zhai's company has received "overwhelming" orders from the US and Europe, and, so far, production has been booked until July.

"If we secure enough workers, we could shore up production and complete orders ahead of time, which bodes well for our profit margin that saw a 15 percent contraction last year," Zhai said.

Similar to Zhai's situation, almost all of the workers at an auto parts firm based in Nantong, East China's Jiangsu Province plan to stay during the holidays, as some worried about the required 14-day quarantine period during which they would lose earnings, according to the plant's owner surnamed Zhao.

Zhao told the Global Times that he expects the stay would shore up production, as orders continuously arrive. He has also been preparing enough inventories for the holidays.

Manufacturers across China - from the southern manufacturing base of Guangdong to the east coastal area like Jiangsu - have painted a bustling and hustling picture in stark contrast to last year's.

"We won't go through the same trajectory as we did last February, when the quarantine and restrictions impeded migrant workers from going out and froze production for months," Duan Lianmin, a manager of a Shenzhen-based glass-making factory, told the Global Times on Tuesday.

Duan said she is betting on exports in 2021, which she expects not only to make up for her losses last year but also to lift the company's revenue to "new heights," as some orders originally flowing from European clients to Vietnam and Southeast Asian economies had returned.

"I think the most difficult time has already gone, and I believe in our country's ability to contain the coronavirus," Zhao said.

A worker makes rice cakes at a food factory in Zhuangzhi Village of Haian, east China's Jiangsu Province, Jan. 16, 2021. Workers in Haian are busy making rice cakes to meet customers' growing demands as the Spring Festival approaches. Photo:Xinhua

Stable supply during holidays

While the global supply chain has been thrown into chaos amid the pandemic, China is an exception. Its daily necessities and material supplies - which are underpinned by a complete industrial chain at home - have played a pivotal role in stabilizing the global price.

"Without Chinese supplies, the world would face an unprecedented inflation that could lead to social unrest and political upheaval," Tian Yun, vice director of the Beijing Economic Operation Association, told the Global Times on Monday. He noted that China has helped bring down the global CPI by about 1 to 2 percentage points.

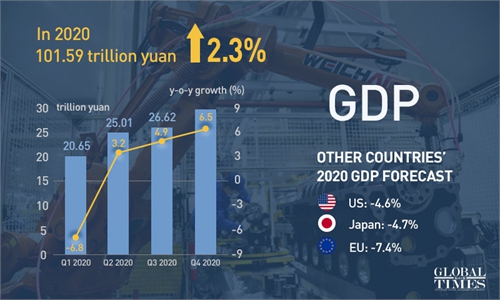

At a Monday press briefing announcing China's 2020 GDP had pass the 100 trillion yuan mark, Ning Jizhe, head of the National Bureau of Statistics, highlighted China's unique edge in building the world's most complete industrial chain, which aided its economic recovery.

Vaccine and medical suppliers are also gearing up for 2021, as surging global demand for personal protective equipment has sent the latter's businesses flying high.

Production lines at vaccine-producer Sinovac Biotech's factories are now running at 24/7, the Global Times learned. The company has been expanding production to increase annual production to 600 million doses. Its inactivated coronavirus vaccines have been exported to quite a number of countries, including Brazil, Turkey, and Indonesia.

Health Box, a domestic supplier of KN95 and N95 masks, saw its orders "increasing substantially" so far this year. The company offers a high protection level and can be used up to 60 times.

"All our staff members will be in place for the New Year holidays and be ready to take turns to work overtime," Huang Yuhao, president of Health Box, told the Global Times on Tuesday. The firms' N95 masks have already received up to 1 billion yuan in orders.

Li Lin, general manager of Anhui Fumei Medical Company, plans to invest in expanding automatic production lines, anticipating another profitable year. "There are rising orders from Italy and the UK, and we're hiring more workers and offering higher salaries to keep up with the demand," Li told the Global Times on Tuesday.

The company's medical exports, including masks and protective outfit, have more than doubled to 900 million yuan last year, according to Li.

A plant manager at a large-sized medical products maker in Dongguan also told the Global Times that her company has been ramping up production since last year and now two additional plants are filled with machines.

The company produces tubes that are used with ventilators, a vital medical equipment used in treating COVID-19 patients. And their largest market is the US.

In 2020, China's medical exports provided a ray of hope for the world plagued by the coronavirus and such export strength is poised to continue as the world battles a new wave of outbreaks, industry observers said.

Between March and the end of December 2020, China exported 224.2 billion masks, 773 million medical protective outift and 2.92 billion pairs of surgical gloves, according to customs data.

The humming factories will boost China's foreign trade in the first quarter. Tian predicts that from January to March, China's exports could rise 20 percent.

However, on the downside, there is pressure on the price of raw materials and labor costs, which some manufacturers worry may affect their profit margins.

Zhang Weiqiang, chairman of Zhongyuan Creative, an electronic goods manufacturer based in Foshan, told the Global Times on Tuesday that the strengthening yuan against the US dollar could dampen prospect for exporters.

He added that he has talked with foreign clients about the rising costs.

In 2020, China's exports grew 3.6 percent to $2.59 trillion, while imports edged down 1.1 percent to $2.06 trillion, customs data showed.