How Dingxiang county in Shanxi Province gains global prominence with small metal flanges

Metal flanges lead Dingxiang to global prestige

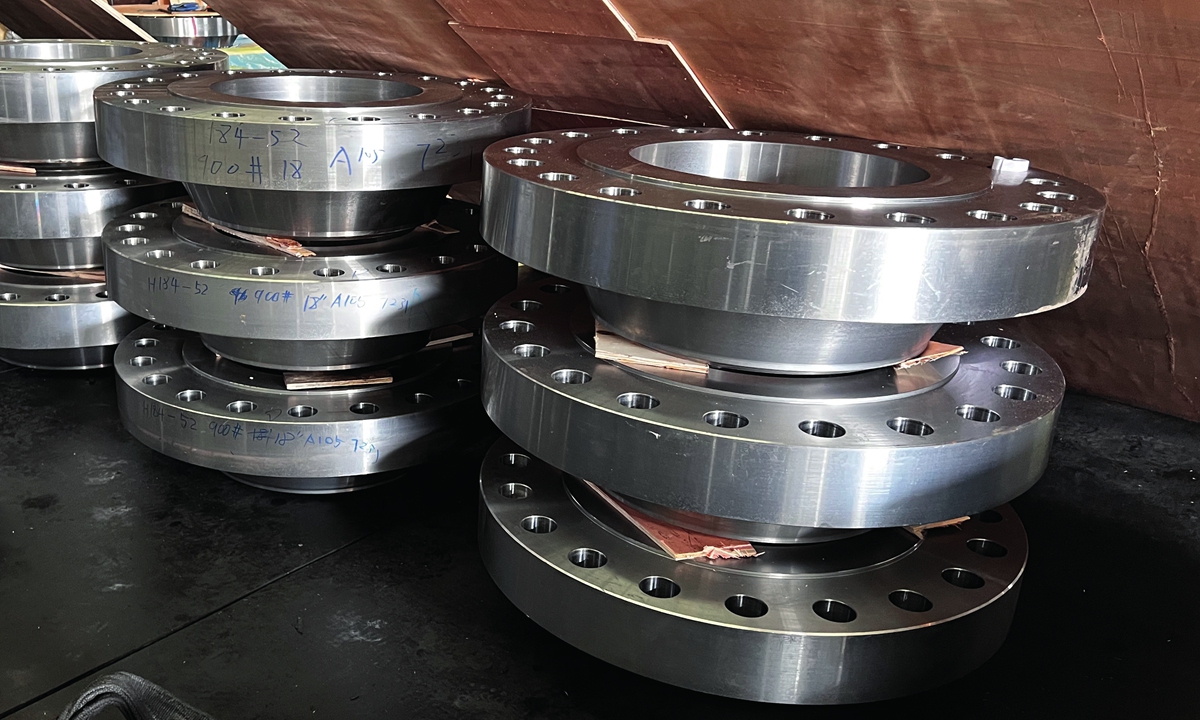

A flange used for wind power turbine is shaped at Shanxi Tianbao Group. Photo: Courtesy of Dingxiang Bureau of Industry and Information Technology

In late 2022, Bright Future, a Chinese television series that recounts the stories of grassroots officials tirelessly leading locals in the fictional Guangming county to prosperity, went viral in China. The series was so popular that it sparked widespread interests and a search for the "real place" in China that inspired the story.

In Bright Future, Guangming county is depicted as the "hometown of flange in the nation." That led many netizens to believe that Dingxiang county in central Shanxi Province is the real-life version of Guangming. Dingxiang has long been known for its robust forging industry, which earned it the name "Hometown of Forging in China."

Specifically, the county is China's largest production and export base for flange, a crucial part used to connect pipes, valves, pumps and other equipment in the petrochemical, water conservancy and electric power, aerospace and other fields.

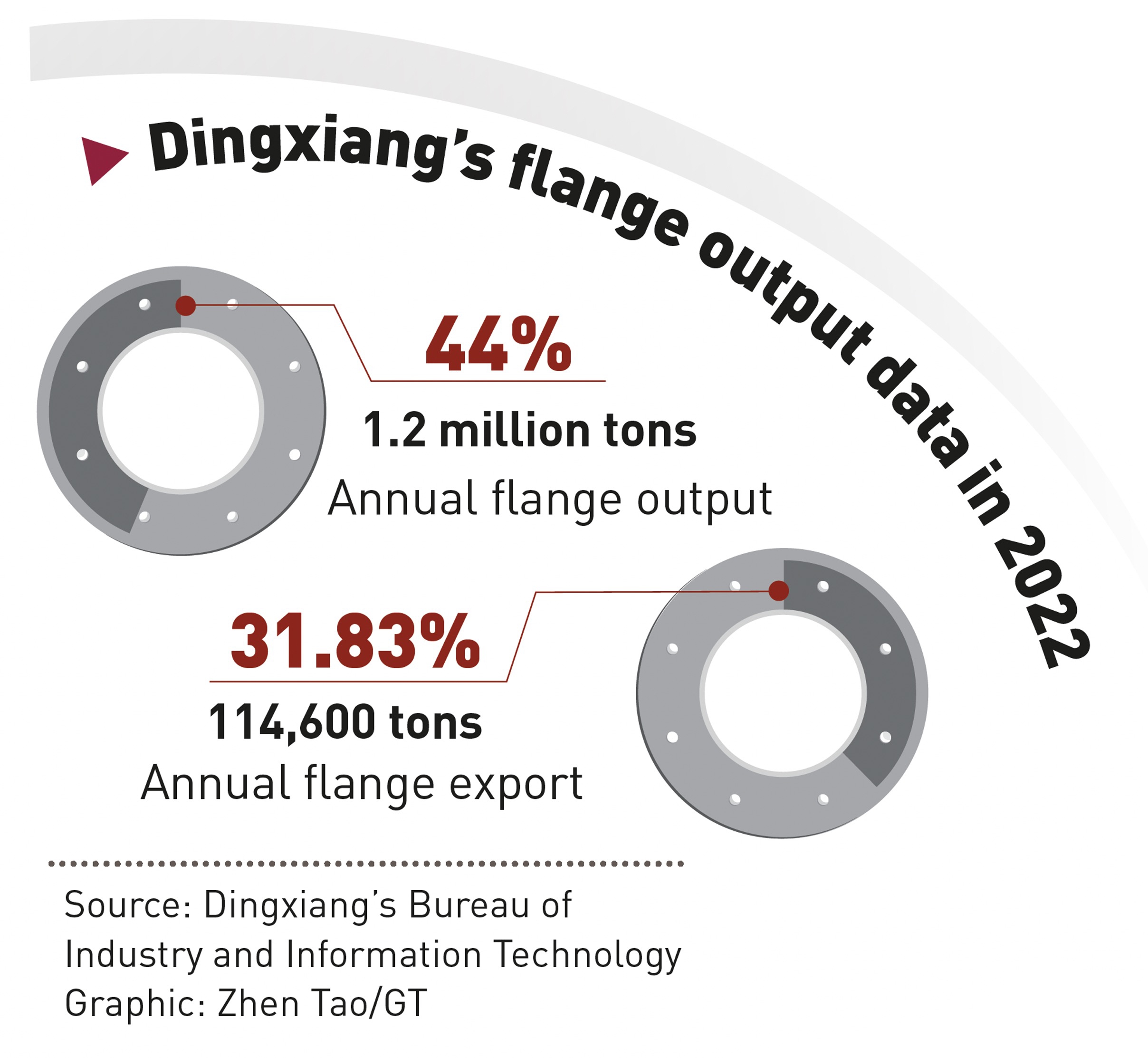

In 2022, the overall output of flange in Dingxiang reached 1.2 million tons with 13.9 billion yuan ($2.01 billion) in sale revenues, which accounted for 44 percent of nationwide flange output, making the town Asia's largest flange production place, data from Dingxiang Bureau of Industry and Information Technology (BIIT) showed.

Dingxiang is also world's largest flange export base with 114,600 tons of export flange in 2022, accounting for 31.83 percent of nation's overall export volume.

Just as how officials in the television series relied on transforming local industries like flange to achieve poverty alleviation and environmental protection and high-quality development, Dingxiang has constantly upgraded its flange industry and expanded its export market around the world to make it an internationally competitive industry - and a steady source for local high-quality development.

Such an effort, vividly on display on factory floors at over 300 iron-forging enterprises in Dingxiang provides a snapshot of China's economic transformation and industrial upgrade in pursuit of high-quality and sustainable development.

Flange products Photo: Tao Mingyang/GT

Heightened resilience

Dingxiang's forging industry has a long history, dating back to ancient times, but it is the hard work of people like Yan Zhilong, deputy general manager of Shanxi Tianbao Group Co, Dingxiang's largest flange producer, that has kept the industry resilient over those years.

"Dingxiang was a battlefield in ancient times and our ancestors were good at forging metal arms and various farming tools, which may be a reason that our homeland has advanced forging industry nowadays," Yan told the Global times on Tuesday.

Yan plans to retire next year after working in the industry for decades. But before his official retirement, he is still working on the manufacturing frontline to secure the quality of each metal part the company produces.

Tianbao produced about 28,000 pieces of flange in different gauges in January 2023, according to Yan. 90 percent of Tianbao's products are used in wind power turbine, connecting each phase of the supportive pillar which may reach several hundred meters high. "Our flange for wind power turbine can be used for 20 years under proper maintenance," said Yan. Tianbao's flange export was halted during the COVID-19 pandemic.

Yan noted that the company's goal in 2023 is to lift the output value to one billion yuan from 800 million yuan in 2022.

Another local forging giant, Shanxi Guanjiaying Flange Forging Group Co, which was established in 1988, can produce 268 flange products from 15 millimeters to 5,000 millimeters used in oil & gas chemical, engineering and transport industry.

After over three decades of development, the company has gained nearly all flange standard certificates in the world and exported flange to over 30 countries and regions, clinching cooperation contracts with international corporations including Shell and BP as well as China's three major energy companies of CNPC, Sinopec and China National Offshore Oil Corporation.

"At present, orders from overseas clients accounted for 50 percent and valued at 300 million yuan annually, while our company started to reach domestic buyers from 2012," said Xu Yuanfei, vice general manager of the company.

Due to the expansion of global energy trade, the export of Guanjiaying Flange Co was barely affected during the pandemic. Xu said that there are about 120 million yuan of orders in hand now. According to the data from Dingxiang BIIT, Dingxiang had 302 forging enterprises and over 40,000 trained industrial workers as of now.

Graphic: Zhen Tao/GT

Greater ambition

Despite its traditional advantages, Dingxiang's flange industry is facing many challenges, including the US' trade war and its push for an economic decoupling, according to a representative from Dingxiang.

"Some overseas buyers in the US and the Middle East have to turn to flange suppliers in India or Vietnam owing to relatively lower cost there," said the representative, while noting that local exporters are looking for more opportunities in Russia and other markets.

However, local officials and companies are actively moving to explore more global markets, especially along the Belt and Road Initiative routes.

In January 2018, the Shanxi AEON International Logistics Park located in Dingxiang county put into operation bonded warehouse and export supervision warehouse, which could handle the export business of Dingxiang flange on the spot. The county has also built a national flange forging product quality supervision and inspection center, established an experts' work station, and actively expanded international cooperation, according to Xinhua.

Meanwhile, the local effort to promote the high-quality development continues. The Dingxiang county government on February 18 held a conference themed with high-quality development for local flange industry in Beijing, moved to further consolidate the industrial advantage so far.

Dingxiang authority vowed to realize 10-12 percent of year-on-year increase of local metal forging industry by the end of 2023, raising the output volume to 1.32-1.44 million tons.

Zhang Hong, president of Dingxiang Flange Forging Association, told the Global Times on Tuesday that it is necessary to transform local flange producers into high-end suppliers in order to gain more profits.

And that has been the focus of both the local government and enterprises, as they moved to upgrade capacity as well as efficiency.

"Dingxiang government encouraged flange enterprises to replace coal by natural gas gradually, and implemented nitrogen reduction devices to ease the impact to surrounding environment," said Yan.

Also, Dingxiang may have found another opportunity to promote the local flange industry in the popularity of Bright Future. At the conference for high-quality development in Beijing, Dingxiang invited the screen writer of the television series, Wang Xiaoqiang, a native of Dingxiang, to talk about high-quality development in both sectors.