Taiwan quake highlights potential shifts in global chip sector’s distribution: experts

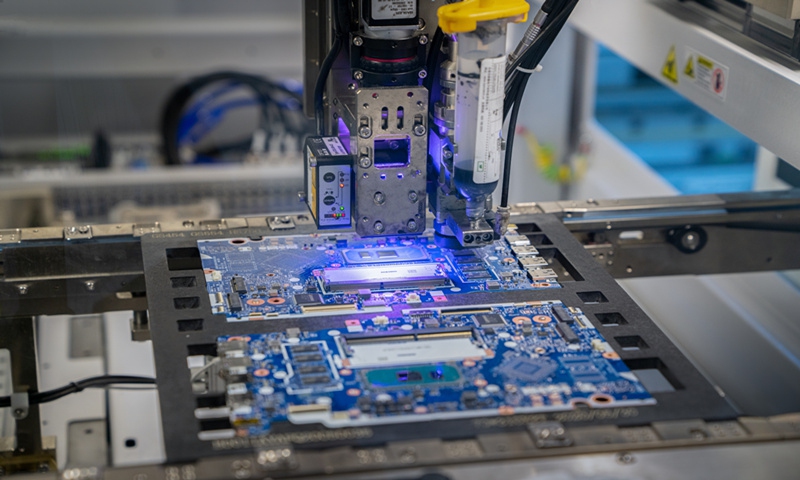

A chip manufacture machine Photo: VCG

After a massive earthquake on April 3, Taiwan Semiconductor Manufacturing Co (TSMC) on Friday confirmed that most equipment in its Taiwan wafer fabs had recovered and its full-year revenue would not be affected, aiming to ease concerns of a potential hit to global semiconductor supplies.

Experts stressed that recurrent seismic activity on the island poses a potential long-term risk to the semiconductor industry, prompting further shifts in the chip supply chain to other regions. That's possible even though the short-term impact on TSMC's chip supply remains relatively limited due to the company's comprehensive quake prevention measures.

Chip firms on the island face multiple risks. The natural environmental risks, along with geopolitical factors, and the US clampdown on China's high-tech development, could further drive the global chip sector's relocation from the island, Wang Jianmin, a senior cross-Straits expert at Minnan Normal University in East China's Fujian Province, told the Global Times on Saturday.

The Taiwan island on Wednesday was hit by the strongest earthquake in nearly 25 years, affecting major semiconductor firms such as TSMC. As the main contract chipmaker to Apple and Nvidia, TSMC plays an outsized role in the global chip supply chain.

According to media reports, earthquakes have disrupted chip production lines, including TSMC's, causing wafer breakages and downtime. This has affected Nvidia's artificial intelligence chip manufacturing and prompted overseas memory factories like Samsung to suspend quotations temporarily.

The company responded that apart from some heavily affected production lines in areas that experienced a greater impact, equipment in Taiwan fabs had largely fully recovered as of Friday, according to the Economic Daily News.

The limited impact and swift recovery stem from TSMC's main facilities being situated in areas that are relatively distant from the epicenter on Taiwan's eastern side, Ma Jihua, a veteran telecom observer, told the Global Times on Saturday.

Although advanced fabs may have survived the earthquake with minimal damage, it's important to note that supporting infrastructure could face significant disruption, such as power plants. These fabs rely on consistent power, but the island's electricity supply issues could be a major long-term vulnerability for its chip production, Ma said.

On Wednesday, the Taiwan region reported power outages and line tripping at plants and substations due to the earthquake, causing unit shutdowns, especially in Hualien and Taichung.

The short-term impact of the earthquake on the chip sector is minimal due to companies' long-term supply arrangements and inventory reserves. Despite this, the region's firms still face risks beyond domestic energy shortages and high production costs, including broader geopolitical pressures such as the US election and tensions between China and the US, Ma added.

In a bid to allay public concerns, TSMC announced in a statement on Wednesday that the company is adept at earthquake response and prevention, with swift recovery rates exceeding 70 percent for wafer fab equipment within 10 hours of the earthquake. Newly built fabs achieved a recovery rate of more than 80 percent, according to the Economic Daily News.

Chip manufacturing is highly sensitive due to strict precision requirements and susceptibility to external factors. In addition to the tangible impact on the sector, the market's anticipatory response holds greater significance. Concerns over future risks to Taiwan's chip industry may influence the upcoming industrial adjustments, experts said.

Global Times