Chinese researchers develop world's first large-area 2D metal material, unlocking future tech revolution

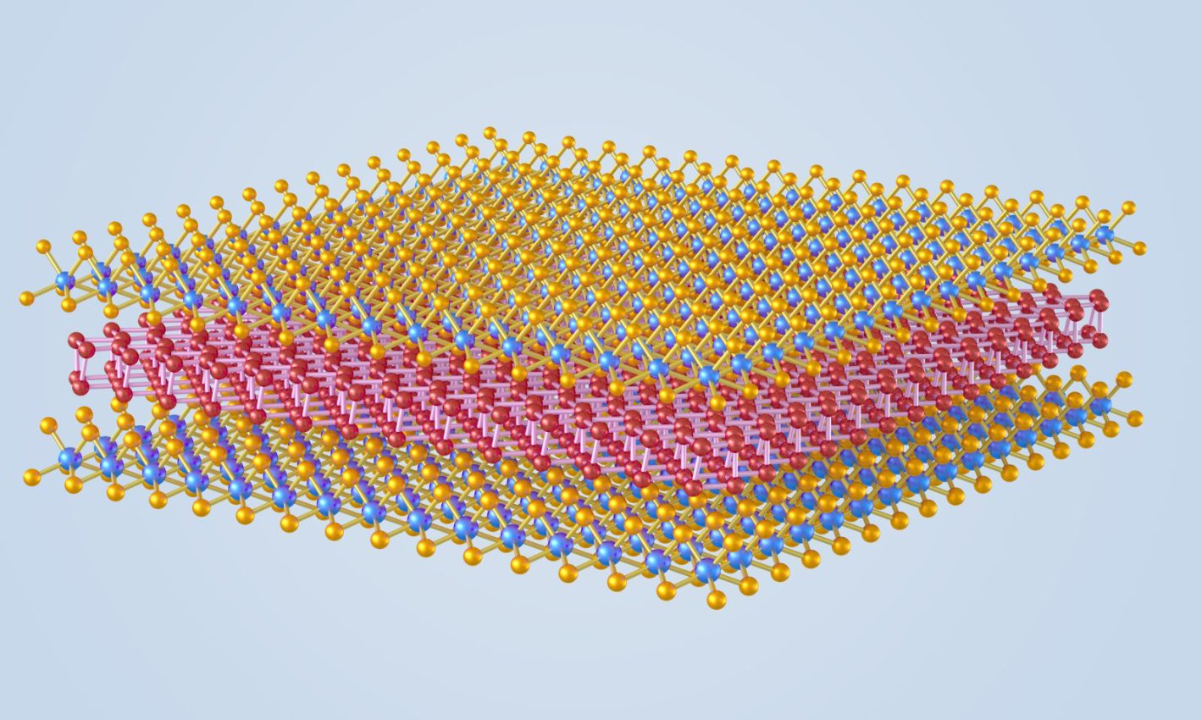

Single-layer bismuth encapsulated by single-layer molybdenum disulfide Photo: Courtesy of the Institute of Physics of the Chinese Academy of Sciences

A Chinese research team has successfully developed a single-atom-thick metal layer, with a thickness just one two-hundred-thousandth of a human hair's diameter, achieving the world's first large-area production of two-dimensional (2D) metal materials, the Global Times learned from the research team on Thursday.

This innovative material, developed by researchers at the Institute of Physics (IOP) of the Chinese Academy of Sciences, opens up a new frontier in 2D metal research, and it holds the potential to revolutionize technologies such as ultra-small, low-power transistors and transparent displays, the research team said.

This achievement marks the first successful fabrication of large-area 2D metal materials, which have great stability in various environments. "Previously, thin metal layers on a small scale were highly unstable. Our team has now developed environmentally stable 2D materials for the first time that show no performance decline even after a year," according to a news release the research team sent to the Global Times.

As mentioned in the release, these 2D metals have a thickness equal to a single atom, measuring just one-millionth the thickness of an A4 sheet of paper and one two-hundred-thousandth the diameter of a human hair.

In scientific terms, genuine 2D materials are defined as those with a thickness of one or a few atoms. However, creating metal materials this thin has long been a significant challenge for scientists.

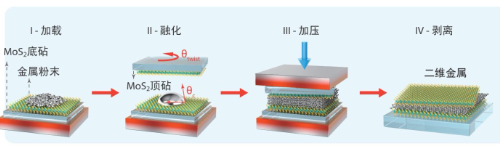

The IOP research team, led by Zhang Guangyu, developed an atomic-level manufacturing technique called van der Waals (vdW) squeezing. This method uses a specially designed anvil made of atomically flat vdW materials with no dangling bonds on its surface, per the release.

The research team melted metals and squeezed them using high-quality single-layer molybdenum disulfide (MoS₂) vdW anvils, which they had previously prepared. This process enabled the consistent fabrication of 2D metals, such as bismuth, tin, and lead, at the atomic thickness limit.

"This breakthrough is poised to herald a new era in the study of 2D metals, paving the way for further technological advancements in areas such as ultra-miniature low-power transistors, high-frequency devices, transparent displays, ultra-sensitive sensors and highly efficient catalysis, among other fields, " Zhang noted.

"Moreover, the vdW squeezing technique has opened up an effective atomic-level manufacturing pathway for 2D metal alloys, amorphous materials, and other non-layered 2D materials, painting a promising vision for a wide range of emerging quantum, electronic and photonic device applications," Zhang added.

Du Luojun, another researcher at the IOP, emphasized that the realization of single-atom-thick metals goes beyond the current vdW layered material systems, filling a critical gap in the 2D material family.

The research findings were published in the international academic journal Nature under the title Realization of 2D metals at the ångström thickness limit on Thursday.

Fabrication process of 2D metal materials through the atomic-level manufacturing technique called van der Waals (vdW) squeezing Photo: Courtesy of the Institute of Physics of the Chinese Academy of Sciences