IN-DEPTH / IN-DEPTH

Young engineers build world's first onboard carbon capture and storage system, contribute Chinese solution to green devt

Rowing against the current

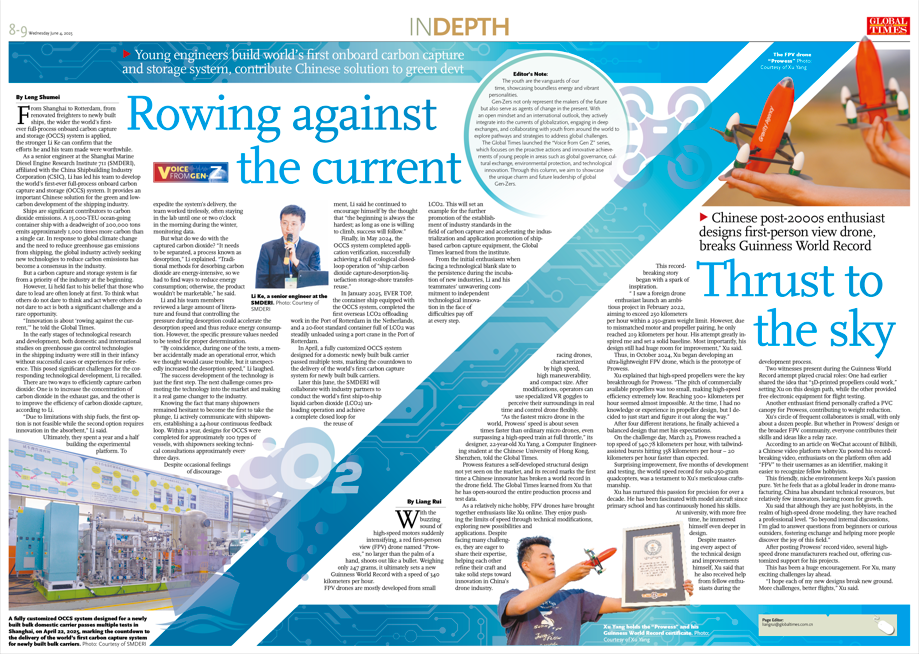

A fully customized OCCS system designed for a newly built bulk domestic carrier passes multiple tests in Shanghai, on April 22, 2025, marking the countdown to the delivery of the world's first carbon capture system for newly built bulk carriers. Photo: Courtesy of SMDERI

From Shanghai to Rotterdam, from renovated freighters to newly built ships, the wider the world's first-ever full-process onboard carbon capture and storage (OCCS) system is applied, the stronger Li Ke can confirm that the efforts he and his team made were worthwhile.

As a senior engineer at the Shanghai Marine Diesel Engine Research Institute 711 (SMDERI), affiliated with the China State Shipbuilding Corporation Limited (CSSC), Li has led his team to develop the world's first-ever full-process onboard carbon capture and storage (OCCS) system. It provides an important Chinese solution for the green and low-carbon development of the shipping industry.

Ships are significant contributors to carbon dioxide emissions. A 14,000-TEU ocean-going container ship with a deadweight of 200,000 tons emits approximately 1,000 times more carbon than a single car. In response to global climate change and the need to reduce greenhouse gas emissions from shipping, the global industry actively seeking new technologies to reduce carbon emissions has become a consensus in the industry.

But a carbon capture and storage system is far from a priority of the industry at the beginning.

However, Li held fast to his belief that those who dare to lead are often lonely at first. To think what others do not dare to think and act where others do not dare to act is both a significant challenge and a rare opportunity.

"Innovation is about 'rowing against the current,'" he told the Global Times.

In the early stages of technological research and development, both domestic and international studies on greenhouse gas control technologies in the shipping industry were still in their infancy without successful cases or experiences for reference. This posed significant challenges for the corresponding technological development, Li recalled.

There are two ways to efficiently capture carbon dioxide: One is to increase the concentration of carbon dioxide in the exhaust gas, and the other is to improve the efficiency of carbon dioxide capture, according to Li.

"Due to limitations with ship fuels, the first option is not feasible while the second option requires innovation in the absorbent," Li said.

Ultimately, they spent a year and a half building the experimental platform. To expedite the system's delivery, the team worked tirelessly, often staying in the lab until one or two o'clock in the morning during the winter, monitoring data.

But what do we do with the captured carbon dioxide? "It needs to be separated, a process known as desorption," Li explained. "Traditional methods for desorbing carbon dioxide are energy-intensive, so we had to find ways to reduce energy consumption; otherwise, the product wouldn't be marketable," he said.

Li and his team members reviewed a large amount of literature and found that controlling the pressure during desorption could accelerate the desorption speed and thus reduce energy consumption. However, the specific pressure values needed to be tested for proper determination.

"By coincidence, during one of the tests, a member accidentally made an operational error, which we thought would cause trouble, but it unexpectedly increased the desorption speed," Li laughed.

The success development of the technology is just the first step. The next challenge comes promoting the technology into the market and making it a real game changer to the industry.

Knowing the fact that many shipowners remained hesitant to become the first to take the plunge, Li actively communicate with shipowners, establishing a 24-hour continuous feedback loop. Within a year, designs for OCCS were completed for approximately 100 types of vessels, with shipowners seeking technical consultations approximately every three days.

Despite occasional feelings of discouragement, Li said he continued to encourage himself by the thought that "the beginning is always the hardest; as long as one is willing to climb, success will follow."

Finally, in May 2024, the OCCS system completed application verification, successfully achieving a full ecological closed-loop operation of "ship carbon dioxide capture-desorption-liquefaction storage-shore transfer-reuse."

In January 2025, EVER TOP, the container ship equipped with the OCCS system, completed the first overseas LCO2 offloading work in the Port of Rotterdam in the Netherlands, and a 20-foot standard container full of LCO2 was steadily unloaded using a port crane in the Port of Rotterdam.

In April, a fully customized OCCS system designed for a domestic newly built bulk carrier passed multiple tests, marking the countdown to the delivery of the world's first carbon capture system for newly built bulk carriers.

Later this June, the SMDERI will collaborate with industry partners to conduct the world's first ship-to-ship liquid carbon dioxide (LCO2) unloading operation and achieve a complete closed loop for the reuse of LCO2. This will set an example for the further promotion of the establishment of industry standards in the field of carbon capture and accelerating the industrialization and application promotion of ship-based carbon capture equipment, the Global Times learned from the institute.

From the initial enthusiasm when facing a technological blank slate to the persistence during the incubation of new industries, Li and his teammates' unwavering commitment to independent technological innovation in the face of difficulties pay off at every step.