Tesla rolls off its 9 millionth vehicle at its Shanghai Gigafactory: company release

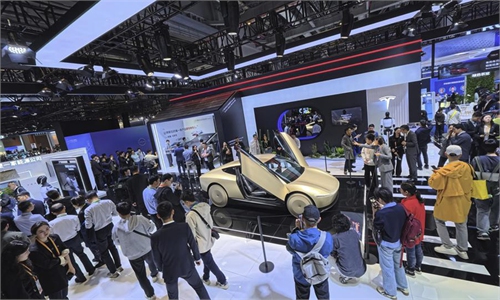

This photo shows the production ceremony for its 9 millionth vehicle at US carmaker Tesla's Gigafactory in Shanghai, on December 30, 2025. Photo: Courtesy of Tesla

US electric vehicle maker Tesla announced on Tuesday that it has rolled off its 9 millionth vehicle at its Shanghai Gigafactory, the company said in a press release sent to the Global Times. A Chinese expert said the milestone reflects China's strong and complete industrial and supply chains.

The milestone vehicle was a white Model Y, a model that Tesla said continues to lead sales in key global markets, the company told the Global Times on Tuesday, describing the development as a new example of "Tesla speed" in China.

Since beginning production in 2019, the Shanghai facility has become a cornerstone of Tesla's global manufacturing network. The plant now accounts for roughly half of Tesla's global production capacity and serves as a major export hub supplying markets across Europe and the Asia‑Pacific region, according to Tesla's statement.

On December 8, Tesla's Gigafactory in Shanghai hit an impressive milestone, producing its 4 millionth vehicle, Xinhua News Agency reported.

The company's Shanghai plant, its first gigafactory outside the United States, began construction in January 2019 and produced its first vehicle in December of that year, Xinhua reported.

In October this year, the Shanghai Gigafactory exported more than 35,000 vehicles — its highest monthly export volume in two years, according to the company.

The speed of Tesla's production shows the high quality and efficiency of China's manufacturing capabilities to produce products that are in high demand internationally, Wang Peng, an associate researcher at the Beijing Academy of Social Sciences, told the Global Times on Tuesday.

It also underscores the factory's strategic role in Tesla's global production footprint and reflects the continued integration of China into the company's manufacturing and supply chain ecosystem, Wang added.

Tesla said that its Shanghai Gigafactory is a key global export hub and production base, playing a vital role in China's manufacturing sector. Tesla highlighted the plant's manufacturing efficiency, noting that its integrated stamping, body, paint and final assembly operations under one roof allow it to produce an entire new vehicle at around every 30 seconds.

The Gigafactory's domestic supply chain localization rate has reached about 95 percent, and a dense supplier ecosystem in the Yangtze River Delta — including cities such as Suzhou, Ningbo and Nantong within a "four-hour circle" — has helped cut logistics costs and accelerate parts supply, said the company.

"The selection of suppliers for Tesla's production sites worldwide is based on the same rigorous, objective standards — quality, total cost, technological maturity and long‑term continuity of supply," Tesla said in the statement, adding that it will continue to deepen roots in China and work alongside the local supply chain.

The site now works with more than 400 first‑tier suppliers; over 60 of these suppliers have been integrated into Tesla's global supply chain, according to Tesla.

Beyond passenger cars, Tesla's presence in Shanghai has extended into energy storage. In February 2025 Tesla's Megapack energy storage plant in Shanghai's Lingang New Area began operations —the first of its kind built by Tesla outside the US. The Megafactory project is planned to produce up to 10,000 energy-storage battery Megapacks annually, with a total storage capacity of nearly 40 GWh, to supply the global market.