Chinese company launches automated production line for robot joints, step toward humanoid robots’ mass production

Embodied AI products are on display at the World Artificial Intelligence Conference (WAIC) 2025 exhibition area in Shanghai on July 28, 2025. Photo: Zhang Weilan/GT

A Chinese robotics company put its automated production line for robot joints into operation on Sunday, marking a key leap for the embodied artificial intelligence (AI) industry to progress from technology research and development (R&D) to large-scale manufacturing, according to a post on the WeChat account of Shanghai's Pudong local district government on Sunday.

As joints are the core of a robot's power system and motion control and account for nearly half of the cost of making a humanoid robot, the breakthrough also lays a solid foundation for the accelerated large-scale application of humanoid robots, a Chinese analyst said.

The existing production line for robot joints, built by Chinese robotics component supplier Jiangsu EYOU Robot Technology Co, has an annual capacity of 100,000 units, while the planned expansion will lift the total capacity toward 300,000 units, "providing downstream complete-machine companies with unprecedented production capacity assurance," the post noted.

The company is the designated supplier for the world's first batch of mass-produced humanoid robots, the Shanghai-based robotics firm AGIBOT's A2 series.

According to a recent post on EYOU 's official WeChat account, the automated production line, the world's first, has solved the long-standing consistency problem faced by robot joints by deeply integrating automation and standardization, "so as to address the demands of humanoid robots for high precision and high stability."

Through continuously optimized engineering solutions, the production line can achieve a first-pass yield exceeding 95 percent while maintaining high performance standard, thus significantly reducing manufacturing costs, read the post.

Although AI and motion algorithms have enabled robots to perform complex actions such as running, jumping, and backflips, the development of cutting-edge laboratory prototypes still relies on manual tuning and assembly by engineers, making it difficult to support large-scale production. The automated production line represents a key breakthrough precisely addressing this challenge, according to the post by the Pudong government.

EYOU founder Sun Zeju was quoted as saying in the post that the launch of the production line marks the transition of humanoid robot core component manufacturing from the "handcraft workshop" era into the "precision intelligent manufacturing" era. This transition aims to meet the future mass production needs of humanoid robots at scales of tens of thousands or even hundreds of thousands.

Wang Peng, an associate research fellow at the Beijing Academy of Social Sciences, told the Global Times on Sunday that he expected the mass production of robot joints would significantly cut the production cost, driving the penetration of humanoid robots from industrial scenarios into the consumer market.

It is believed that such technological progress "would further solidify China's leading position in the global industrial chain as well as the mass application of humanoid robots," he noted.

Wang highlighted China's overwhelming edge in such areas as a complete manufacturing supply chain, strong industrialization capabilities, humanoid robot body manufacturing, abundant application scenarios and high-dynamic motion algorithms compared with foreign rivals, he noted.

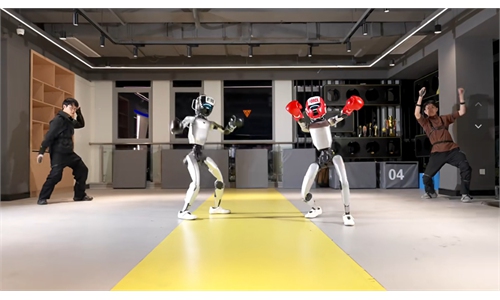

Zhang Yunming, vice minister of the Ministry of Industry and Information Technology, said at a press briefing on Wednesday that at present, China's humanoid robots have rapidly transitioned from the period of "standing firmly, walking steadily, and running fast" to the new level of "performing on stage, competing on the track, being used in homes and working in factories."

In 2025, the number of domestic complete-machine humanoid robot companies exceeded 140, with more than 330 humanoid robot products having been released, he said.