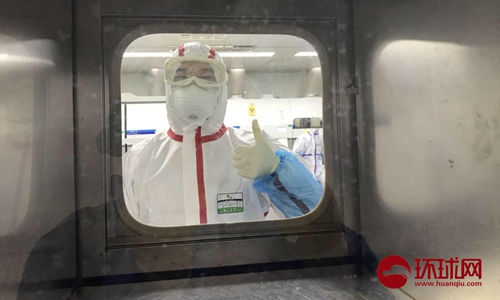

Huo-Yan Laboratory in Wuhan, Central China's Hubei Province Photo: Global Times

Although the COVID-19 situation is gradually abating in China, nucleic acid tests are becoming a larger part of people's daily lives as the country has been conducting widspread testing to ensure a safe work resumption.

How does the test actually work? The Global Times reporter visited the Huo-Yan Laboratory in Wuhan run by China's genomics giant BGI on Wednesday afternoon, to take a closer look.

Huo-Yan Laboratory in Wuhan, Central China's Hubei Province Photo: Global Times

The laboratory for the virus detection is one of the government's designated COVID-19 test bases in Wuhan, Central China's Hubei Province, also the city that has been hit hardest across the country. Since being put into use on February 5, the lab has completed tests for more than 300,000 people in Hubei, with a testing capacity of 20,000 samples per day.

When visiting the place, Zhang Chi, a lab employee, explained the thorough testing process to the Global Times reporter: first, the sample will be sent to inactivation, then for an information review, followed by liquid separation and packaging, automated nucleic acid extraction, and then comes the final step of a Polymerase chain reaction (PCR) test.

According to BGI's protocols, the final report has to be delivered within 24 hours.

All of the above-mentioned processes were conducted in a "very inconspicuous" building. When walking in the corridor, the Global Times reporter could hear the "wind" blowing as many air ducts and fans are working to maintian negative pressure in the lab.

The lab was designed according to P2 standards and adpoted a biosafety level 3.

Samples for inspection are usually packed into a foam box. After the sample delivery point is sprayed and disinfected with alcohol, the foam box will be sent to the inactivation chamber through a transfer window. The inactivation process can make the COVID-19 virus non-infectious.

Then, the lab staff will upack the box in a biological safety cabinet and take out the samples one by one.

"Sample unpacking and other procedures must be carried out in a professional biological safety cabinet to ensure the safety of lab employees and the environment," Zhang said.

Inactivated samples will then be sent to the information review room. To ensure information accuracy, BGI said it requires every sample to display a barcode with the owner's personal information, noting that information accuracy is a very crucial part of the test.

Huo-Yan Laboratory in Wuhan, Central China's Hubei Province Photo: Global Times

"Each sample is put into a ziplock bag, so that even if one sample has an issue, it will not contaminate others," Zhang said.

Zhang highlighted that point because BGI has vast experience in medical testing and has quickly implemented strict management regulations for each step. For example, for transshipment, the outer packaging of the sample should be wrapped in a separate plastic wrap to prevent the sample from moving.

The Global Times reporter also observed that lab staff who transferred the samples would use 75 percent medical alcohol to sterilize both the handle and platform of the transfer window before putting samples in the window.

The application of automated equipment is an important reason for the improvement in detection capabilities, Zhang said, noting that with BGI's self-developed automated sample preparation system, it can achieve nucleic acid extraction in one step - one machine can complete 192 sample extractions within 80 minutes.

As a nationwide work resumption has increased demand for nucleic acid tests, on March 5, BGI's Wuhan lab received 16,000 samples in one day.

Apart from Wuhan, BGI has also built Huo-Yan labs in 12 major cities across the country, including Shenzhen in South China's Guangdong Province, Beijing and Shanghai. The firm has so far completed tests for 600,000 people in China and its Shenzhen lab has completed tests for 300,000 of them. With a current testing capacity of 60,000 people per day, BGI said if necessary it can increase that rate based on demand.

Huo-Yan Laboratory in Wuhan, Central China's Hubei Province Photo: Global Times

Serving as a crucial part in China's strategy to contain the pandemic, BGI's Huo-Yan Lab has also been replicated in other countries around the world.

BGI has helped build Huo-Yan Labs in Brunei and UAE, which have already been put into use, and it will also help build two COVID-19 testing labs in Serbia, to achieve total daily tests of 3,000 - triple the current level, according to a statement on the website of the Serbian government. The company is also negotiating with governments or partners in more than 10 countries and regions to build additional labs.

Key equipment made by BGI for its Huo-Yan Laboratories has also arrived in the US and Sweden. On March 22, BGI delivered the first batch of automated virus nucleic acid extraction equipment and test kits to Kansas, USA, and will also ensure the subsequent transportation of automated equipment and other supplies.

BGI will also jointly establish a test lab with a Swedish University in Stockholm that could reach a testing capacity for 10,000 people, and monitor virus variation in a comprehensive and multi-omics manner.

So far, orders for BGI's international COVID-19 test kits have reached tens of millions, covering more than 80 countries and regions.