Chip shortage slams brakes on car sector

Domestic firms could find new opportunity amid global supply crisis

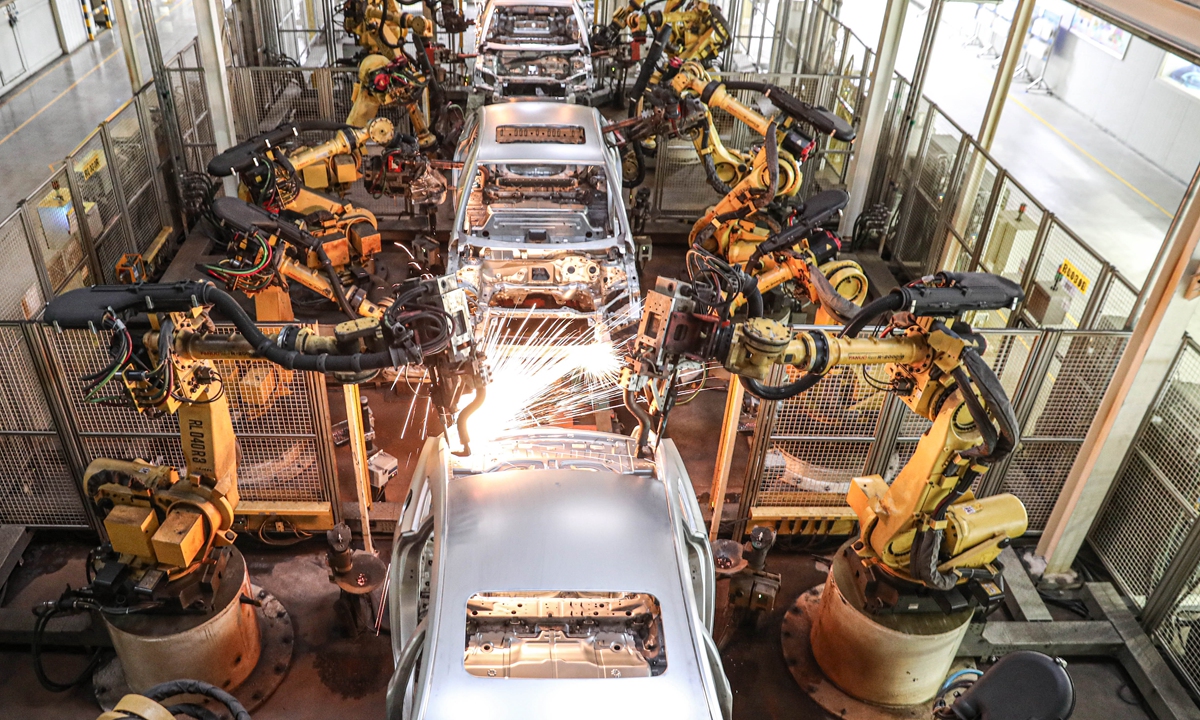

The automated production line at a car factory in Shenyang, Northeast China's Liaoning Province. Meng Wei, spokesperson from National Development and Reform Commission said recently that China's auto production and sales will reach about 25 million in 2020, and China's auto industry is expected recover to the previous year's level. Photo: IC

After rebounding from the fallout of the COVID-19 pandemic at a speed beating most carmakers' original expectations, China's auto industry now faces a new dilemma - tightening supplies of semiconductors, which serve a key role as a vehicle's brain from controlling acceleration to steering and braking.

Toyota Motor Corp has resumed production in Guangzhou, capital of South China's Guangdong Province, which it temporarily halted due to a shortage of chips, and the specific impact is being assessed, the Japanese carmaker told the Global Times on Wednesday.

Toyota halted operations on its third line at GAC Toyota Motor, the joint venture with China's GAC Group, for two days, the Nikkei Asia reported.

Ford Motor, Fiat Chrysler Automobiles and Nissan Motor have also said they would cut output in January due to a lack of chips, according to media reports.

The global shortage of semiconductors has brought great challenges to the world's vehicle industry, and may even affect normal production.

"Given the importance of the auto manufacturing industry, this could have a major knock-on effect on employment and the overall economy. Therefore, we are working closely with suppliers to solve the potential impact of the global semiconductor shortage on production, fully prepare the distribution plan for semiconductors, and give priority to ensuring production of the company's core models," Ford China told the Global Times on Wednesday.

Industry insiders said the chip shortage could become more severe next month and cause volatility in the automobile sector.

The chip shortage will have a certain impact on global auto production for some time, affecting the stability of China's vehicle industry, the largest worldwide, according to the China Association of Automobile Manufacturers (CAAM).

Chen Shihua, vice secretary general of the CAAM, said that the shortage of chips, which emerged in December, will have a great impact on output in the first quarter of 2021, and the impact might continue into the second quarter.

German automaker Volkswagen said last month that it faced a shortage in the supply of semiconductors and would adjust production at facilities in China, North America and Europe. Meanwhile, it is working on the issue closely with business partners.

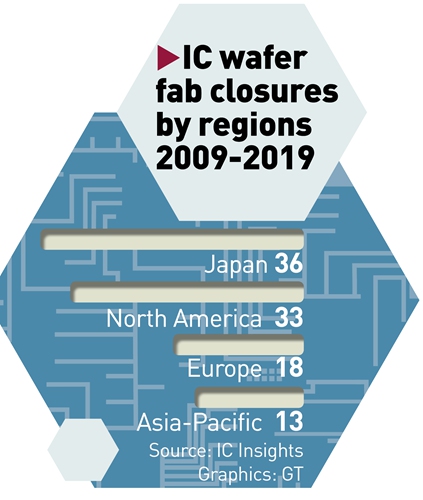

Jia Ke, chief editor of Auto Business Review and co-founder of Autosquare Vehicle app, told the Global Times on Wednesday that China's auto sector rebounded at a better-than-expected pace last year after the COVID-19 disruptions, yet most carmakers did not plan sufficiently to ensure output. Meanwhile, production of microchips was reduced in Europe due to the raging pandemic, so a bottleneck occurred.

"Moreover, we can see that the consumption of consumer electronics means robust demand for chips, which means the limited capacity now becomes tighter," said Jia.

The kind of chips that Volkswagen lacks is reported to be microcontrollers used in the electronic stability program, which is mainly provided by German auto parts supplier Continental.

"Most middle- and high-end cars in China, especially sport utility vehicles, should be equipped with these chips as part of the safety system," said Zhou Yanwu, research director at Zuosi Auto.

Zhou told the Global Times on Wednesday that among domestic vehicle producers, the chip supply for Geely might be affected since it also sources products from Continental.

A Geely PR employee told the Global Times on Wednesday that there is no chip shortage at the company.

According to a Geely teleconference in December, the company is using chips already in inventory. Compared with luxury brands like Benz, BMW, Audi and Volkswagen, Geely has lower demand for such chips.

"It is a potential threat to both multinationals and domestic manufacturers. The only difference is the extent of the impact," Jia said.

Bosch and Continental, the two European largest car component makers, acknowledged the chip issue last month after Volkswagen's announcement and have been trying to limit the impact on customers.

The normal delivery period in the semiconductor sector is six to nine months, and this means that production has been unable to respond quickly to the unexpectedly rapid growth of the auto industry, Continental said in a note sent to the Global Times on Wednesday.

"The bottleneck in auto semiconductor parts is expected to continue into 2021, which will have a serious impact on Continental's production. With the intense attention of our executive board, the internal working group is working around the clock to deal with the current critical situation," the supplier said.

Facing this crisis, some automakers have begun sniffing out potential opportunities as more imported chips are replaced with domestic ones in some segments, Jia said.

For example, more locally produced front cameras - which are more closely related to safety than rear cameras - are being used in cars instead of the previous preferred choices by automakers.