Baihetan project takes lead in hydropower technology in the world: engineers

Green energy maverick

The Baihetan Dam opens to release water. Photo: Lin Xiaoyi/GT

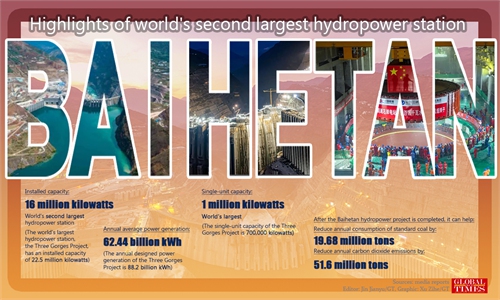

The Baihetan Hydropower Station in Southwest China, the world's largest and most technically challenging hydropower project currently under construction, has recently began operations while the Chinese people celebrate the 100th anniversary of the founding of the Communist Party of China (CPC).The hydropower station stands on the Jinsha River, an upper stretch of the Yangtze River, at a cost of 220 billion yuan ($34.07 billion). It will be China's second largest hydropower project only after the Three Gorges Dam once it is completed.

Since the start of construction of the Baihetan Dam in 2017, the project had to overcome extremely difficult technical challenges, breaking a number of world records including the largest underground caverns, the largest anti-seismic parameters of a 300-meter high dam, and the largest spillway caverns.

Hydropower Specialists noted that since the construction of the Three Gorges Dam, China's hydropower industry has developed at a tremendous pace. China moved from being a "follower" to becoming a world leader in sustainable energy.

At present, the operation of Baihetan Hydropower Station highlights that China's hydropower projects are not only the largest in the world but more importantly, that China has mastered the core technology to create a brand new framework for the usage of water resources and hydropower engineering in the globe.

Mega hydropower station hidden in mountain

The hydropower station, situated on the border of Sichuan and Yunnan provinces, will have a total installed capacity of 16 million kilowatts produced by 16 generating units with a capacity of 1 million kilowatts each, the largest single-unit capacity in the world.

Each of the generating units is more than 50 meters high with a weight of more than 8,000 tons, equivalent to the weight of a destroyer, and an efficiency of up to 99 percent.

"The commissioning of the first two generating units of the Baihetan Hydropower Station reflects the development of China's hydroelectricity generating unit capacity, from 300,000 kilowatts to 700,000 kilowatts, and finally 1 million kilowatts, making it the 'Qomolangma' of the world's hydroelectric industry," He Wei, a deputy director of the Baihetan Hydropower Station Engineering and Construction Department, told the Global Times.

He noted that in the past, China took the path of innovation based on inspiration from advances in science and technology from abroad to build the Three Gorges Dam. But in Baihetan project, despite being challenged by the technological isolation from some countries or the rising price of supplies, China achieved total independent innovation by its own merits.

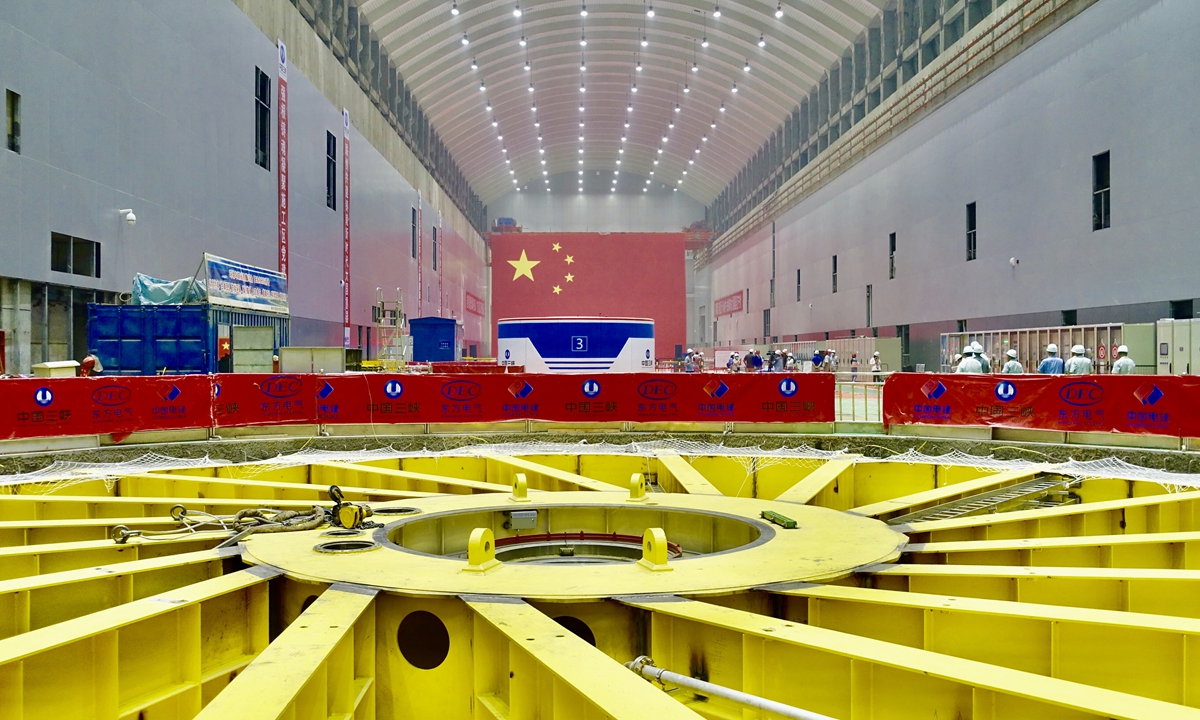

A view of Baihetan Dam's underground power station. Photo: Lin Xiaoyi/GT

In the face of allegations by some Western media outlets claiming that the generators installed in the dam were "brutally copied," Chen Jianlin, Chief Engineer of the Baihetan Hydropower Station, pointed out that some reporters have ulterior motives and lack a basic understanding of the hydropower industry."There is no standardized production model. Each hydropower station is unique because the geological conditions and hydrological environment of each station is totally different. The generating principle of different power units is also distinct," Chen told the Global Times.

Chen noted that the development of a megawatt unit is far more difficult than any other project under construction or in operation in the world. "If there is plagiarism, it is other countries that are copying us," he joked.

In order to accommodate the colossal 16 generating units, two super power stations, 438 meters long and 88.7 meters high, were built under the mountains on both sides of the dam, making them the largest underground power plants in the world.

The total length of the tunnels for power generation and flood control is about 217 kilometers, equivalent to the distance from East China's Shanghai to Ningbo, Zhejiang Province. And the underground chamber required an excavation of 25 million cubic meters, enough to build 10 Egyptian pyramids.

Building a dam in the narrow V-shaped valley of the Jinsha River has space limitations and is faced with extremely complex geological conditions. However, the construction of this "underground city" has only taken about four years to complete.

The world's first 'seamless dam'

The construction of the Baihetan Dam also required significant innovation in China's hydropower engineering equipment and construction techniques.

In the underground chambers on the left bank of the Baihetan Dam, there are three spillway tunnels that have been described as engineering marvels and works of art.

Perhaps they could be called a miracle because each flood tunnel is more than 2,000 meters long, with an overflow area of more than 200,000 square meters. They can withstand a large discharge of more than 12,000 cubic meters per second and a high flow velocity of 47 meters per second, which can fill the entire West Lake (covering an area of 650 hectares, 3 meters deep on average), in just 18 minutes.

A view of Baihetan Dam's spillway tunnel. Photo: Zhao Yang

It looks like a piece of art because the new type of concrete developed by the construction team has a smooth and strong surface, which creates a mirror effect. The average deviation of the entire dam spillway wall is less than 2mm.

"The rock mass in the valley where the Baihetan hydropower station is located is fragile, in addition that the overall shape of the spillway tunnel we designed is like a roller coaster track. At the beginning, the old equipment could not meet the needs of transportation and construction. Difficult technical issues caused many of our vendors to 'run away,' and we couldn't find a new partner even if we paid a higher price," Wang Xiaohai, director of the Baihetan spillway tunnel project, told the Global Times.

Although the supplier left, the team of the spillway tunnel project did not put their work on hold and chose to contact a number of technical teams across the country to review the failures in the construction process and kept adjusting their plan. The team finally developed a safe and efficient equipment, which was put to use improving the overall construction efficiency by about 20 percent.

The flood control capacity of the dam is 7.5 billion cubic meters. After the completion of Baihetan Dam, the flood control standard of cities along the Yangtze River will be further improved to effectively reduce floods in the middle and lower reaches of the Yangtze River, in joint operation of the Three Gorges Dam.

"The Yangtze River used to be a river that people couldn't harness and use, but now, the flood of the Yangtze is no longer a beast but a resource," He said.

At the same time, according to Chen, the Baihetan dam has been embedded with thousands of sensors, which can measure temperature, deformation, stress and other important information. This information is collected and transmitted in real time to the hydropower station's intelligent construction management platform, iDam, which has enabled accurate intelligent control and real-time adjustment of various parameters of the project, making Baihetan the world's most intelligent dam.