Core components of China-made world's largest 'artificial sun' accomplished, new breakthrough in core technology

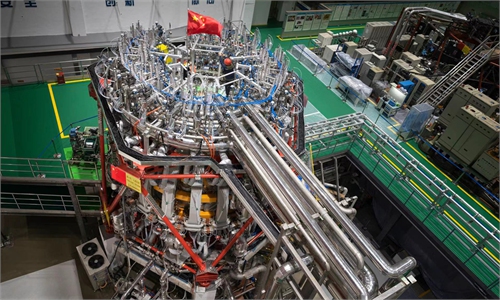

Celebration of the accomplishment of the prototype piece of the enhanced-heat-flux first wall panel of the international thermonuclear experimental reactor, also known as the world's largest "artificial sun," is held in Guizhou Province on November 22, 2022. Photo: Courtesy of the Southwestern Institute of Physics under the China National Nuclear Corporation

Manufacturing of the core components of the next-generation "artificial sun," the full-size prototype of the enhanced-heat-flux (EHF) first wall (FW) panel, has been completed in China with its core indexes being significantly better than its design requirements and meeting the conditions for mass manufacturing, marking a new breakthrough by China in the scientific research of the core technology of EHF FW, the Global Times learned from its research team on Tuesday.

Also known as the world's largest "artificial sun," the international thermonuclear experimental reactor (ITER) for the exploration and development of nuclear fusion energy is one of the largest and most far-reaching international scientific projects in the world, and the largest international scientific and technological cooperation project that China participates in as an equal alongside with the EU, India, Japan, South Korea, Russia and the US.

China signed an agreement on the launch of the ITER project with the other six parties in 2006 and has shouldered responsibility for about 9 percent of its tasks.

A new breakthrough was made in research for the "artificial sun" in China in October, with its HL-2M plasma current exceeding 1 million amperes, setting a new record for the operation of controllable nuclear fusion in the country.

The EHF FW panel, which can withstand a surface plasma ion temperature of the reactor core up to 150 million C, some 10 times hotter than the real Sun, during the operation of the ITER, is the most critical core component of the reactor, involving the core technology of the fusion reactor construction.

The technology mastered by China previously took the lead in passing international certification.

The full-size prototype piece of the ITER EHF FW was developed by the Southwestern Institute of Physics under the state-owned China National Nuclear Corp (CNNC).

After the researchers from the institute manufactured EHF FW fingers in batches, they then completed the welding and assembly of the components by overcoming setbacks such as high temperatures, power cuts and COVID-19 outbreaks by cooperating with Guizhou Aerospace Xinli Technology Co, a company specialized in metal smelting and forging, which is located in Zunyi city in Southwest China's Guizhou Province.

The Chinese team, which took the lead in manufacturing the prototype piece in the international team, once again made a substantial engineering breakthrough for the research and development of the key components of ITER, marking China's solemn fulfillment of its international commitment.

Luo Delong, director of the China International Nuclear Fusion Energy Program Execution Center under the Ministry of Science and Technology, addressed the achievement and said that great achievements have been made by the Chinese team after years of efforts and lots of fruitful research and development work.

Through the work, China has independently mastered the principle of the process and made breakthroughs in technology while also providing "Chinese wisdom" and "Chinese plans," making huge contributions to independently master key technologies, fulfilling international commitments and demonstrating its responsibilities as a major power, Luo said.