Controlling technology transfer to counter India's illegal treatment toward Chinese companies

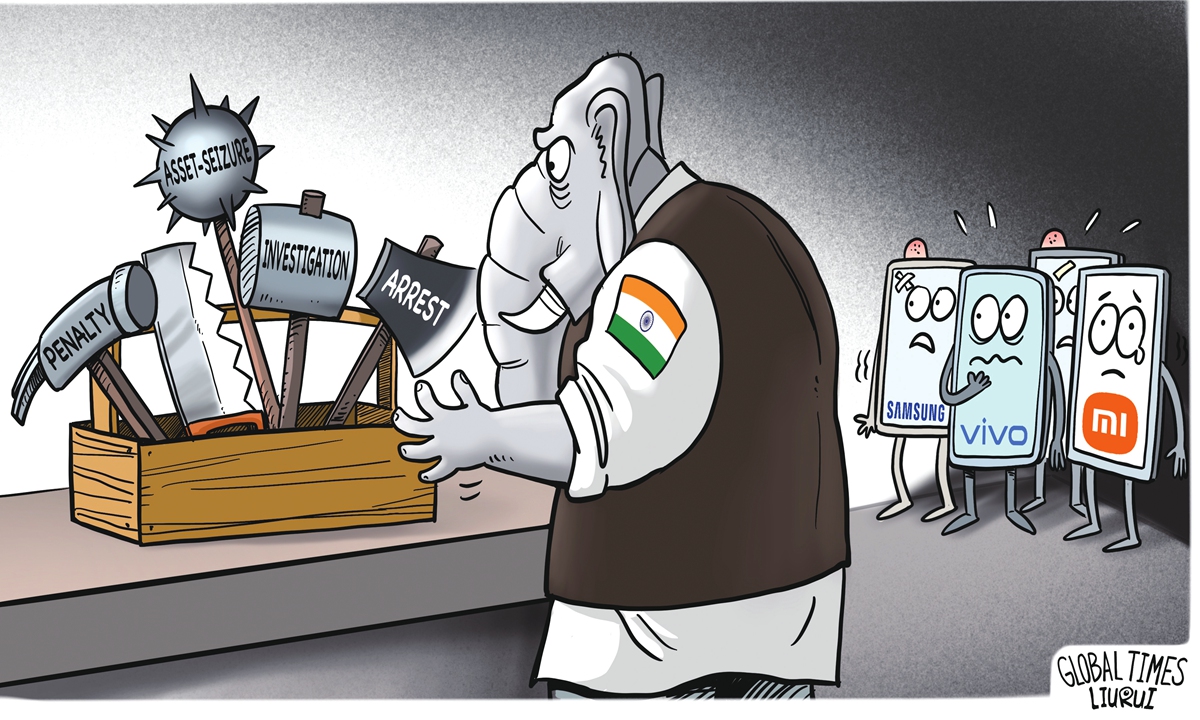

Reckless assault.Illustration: Liu Rui/GT

India has taken a strong stance against Chinese companies by banning Chinese apps, freezing the funds of Chinese companies and arresting their executives.Why is India so emboldened? The reason is that India's mobile phone market has a lot of potential.

Apple plans to shift 25 percent of its production to India by 2025. Chinese mobile phone makers Xiaomi, OPPO and vivo have already achieved manufacturing in India.

India has taken advantage of its market potential to compel Chinese enterprises to relocate their production lines to India by imposing higher tariffs, but when the production lines are completely transferred, India resorts to illegal means to exploit the wealth of these Chinese enterprises. This puts Chinese companies in a dilemma.

Mobile phones have become the most boastful economic achievement of the Narendra Modi government.

According to reports, India produces 11 percent of all mobile phones produced in the world in 2020. The figure was just 3 percent in 2014. India has become the second-largest mobile phone manufacturing country after China, with cumulative shipments of locally produced handsets crossing 2 billion during 2014-2022.

We can observe India's "remarkable advancements" in manufacturing through two other statistics. According to reports, China's share of global manufacturing was 31 percent in 2021, while India was 3 percent. Chinese manufacturing has risen from 6 percent to 31 percent in the last 20 years. Conversely, India reached 3 percent in 2018 and has maintained the same share till today.

It's also worth mentioning that India has a trade deficit of over $100 billion with China, which is increasing.

The comparison of these figures shows that, first, Modi's development of the manufacturing sector is primarily focused on the mobile phone industry, while other manufacturing industries have not shown any significant progress or decline.

Second, India's mobile phone industry mainly relies on assembly, while spare parts production depends heavily on imports from China and other countries. It is not easy for India to change this situation.

Competition among mobile phone companies in India has intensified, leading to Apple, Samsung, and other companies demanding that supporting production enterprises also move to India. China's investment in India's mobile phone and supporting manufacturers has also begun to transfer the production of certain parts and components, and a number of Chinese skilled workers are involved in training Indian workers.

Undoubtedly, we need to take notice of the US-led effort to shift industry away from China and India's focus on mobile phone development, as it has resulted in the relocation of mobile phone assembly lines.

However, this transfer is not going to be smooth sailing in India. The production capacity of its supporting products and the level of labor are both critical factors. Unfortunately, India lacks a large number of workers with practical ability, efficiency, discipline, good learning skills and willingness to work hard.

These two points are also China's manufacturing strengths, which become significant as the US steps up industrial and supply chain restructuring. Therefore, it's crucial to maintain China's advantage in manufacturing.

China's manufacturing industry excels at forging ahead to the high end. It also has the ability to constantly innovate and market mid- and low-end products. This is especially evident in China's manufacturing industry, which has cultivated a large number of highly skilled workers over many years.

We require more substantial policies to aid manufacturers with essential technologies to remain and support skilled workers. For instance, among Apple's 200 core suppliers, about a quarter are Chinese manufacturers, which compete through technology and pricing to secure orders, mastering the technology of leading international products.

Currently, China's manufacturing sector is facing significant challenges and it must not be manipulated by the US. The associated Chinese enterprises need to think how to follow the specific leading companies in making the manufacturing transfer overseas. Failure to address this issue could result in the fragmentation of China's industrial chain.

Local governments need to prioritize retaining production lines for supporting products in important industrial supply chains, including implementing measures to retain skilled workers or transferring to the central and western areas of the country. It is crucial to support key enterprises with stronger industrial subsidies, similar to those provided by the US and Europe.

Retaining these enterprises, technologies and personnel is essential to preserving the lifeline of Made in China, which will enable us to strike back forcefully when India illegally treats Chinese enterprises and counter the impact of the US attempt to decouple from China.

The author is a senior editor with the People's Daily, and currently a senior fellow with the Chongyang Institute for Financial Studies at Renmin University of China. dinggang@globaltimes.com.cn. Follow him on X @dinggangchina