Fast reactor can increase utilization rate of uranium resources 60-fold: chief designer

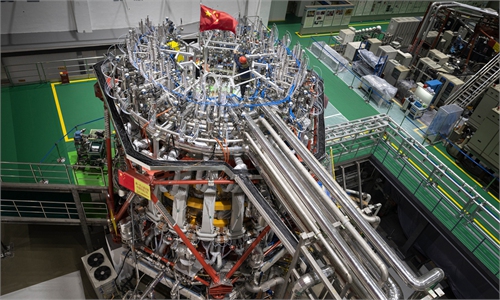

Photo: Courtesy of China National Nuclear Corporation

The reactor shell of Russia's Brest-OD-300 lead-cooled fast reactor in Seversk is nearing completion, nuclear technical journal Nuclear Engineering International reported on Tuesday, citing general contractor Titan-2.

The Brest-OD-300 is under construction at the Siberian Chemical Plant (SCC part of the Rosatom fuel company TVEL) as part of the pilot demonstration power complex ODEK - Opitno Demonstratsionovo Energo-Kompleksa, which is part of the Breakthrough (Proryv) project intended to demonstrate closed fuel cycle technology, according to the report.

About two months before, the magazine also reported that the world's largest multi-purpose sodium-cooled fast neutron research reactor, a 150-megawatt facility, MBIR (Mnogotselevoi Bistrii Issledovatelskii Reaktor), is also expected to start actual operation in 2027. The move will allow Russia to make a major leap in nuclear research.

Since their birth in 1960, fast reactors have been attracting increasing attention around the world because they can provide efficient, safe, and sustainable energy. The closed fuel cycle of fast reactors can support the long-term development of the nuclear power as part of the world's future energy structure and reduce the burden of nuclear waste. Thus, the fast reactor has become one of the development directions of global fourth-generation nuclear power.

As an intermediate link in China's "three-step" nuclear power technology roadmap of "thermal neutron reactor - fast reactor - controlled nuclear fusion reactor," the development of fast reactors has always attracted industry attention. China's first sodium-cooled fast neutron reactor, the China Experimental Fast Reactor (CEFR), located at the Beijing-based China Institute of Atomic Energy (CIAE), under the China National Nuclear Corporation (CNNC), is the cornerstone of China's fast reactor technology development.

According to the International Atomic Energy Agency, sodium-cooled fast reactors are the most mature fast reactor technology, with over 400 cumulative reactor-years of experience gained through the design, construction, operation, and decommissioning of experimental, prototype, demonstration, and commercial reactors in multiple countries including China, France, Germany, India, Japan, Russia, the UK, and the US.

"The fourth-generation nuclear energy system demonstrates a new stage of nuclear energy development with its comprehensive advantages. By establishing a fast reactor nuclear energy system and implementing a closed fuel cycle, uranium resource recycling can be achieved, increasing the utilization rate of uranium resources from less than 1 percent to around 60 percent, and the development of nuclear fission energy is expected to extend from a hundred-year time scale to a thousand-year time scale," Zhou Peide, deputy chief engineer at the China Institute of Atomic Energy and chief designer of China's integrated fast reactor project, told the Global Times during a recent media group visit to the CIAE.

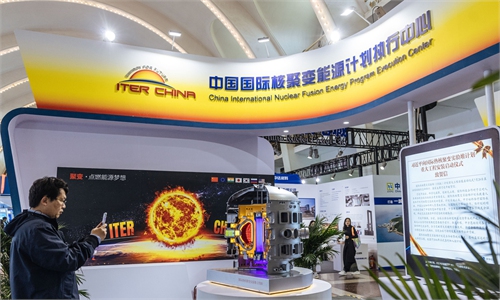

The "thermal neutron reactor - fast reactor - controlled nuclear fusion reactor" strategy was first proposed in 1983 in order to solve the problems associated with the sustainable development of nuclear energy and the long-term safe and effective supply of nuclear fuel in China.

After decades of development, China's thermal reactor technology is becoming increasingly mature, with thermal neutron reactors accounting for over 90 percent of nuclear power generation. Compared to thermal reactor technology, fast reactor nuclear energy systems have advantages such as a high uranium resource utilization rate, a high inherent safety of reactors, and the minimization of high-level waste.

According to Zhou, most third-generation nuclear power reactors are pressurized water reactors, which belong to the category of thermal neutron reactors. The main material used in these reactors is uranium-235, which accounts for only about 0.7 percent of natural uranium in nature. In comparison, fast reactors can fully utilize uranium-238, which accounts for as much as 99.3 percent of natural uranium, increasing the utilization rate of natural uranium to more than 60.

In terms of safety, the working pressure inside the fast reactor vessel is slightly higher than atmospheric pressure, belonging to a low-pressure system with the working temperature of the coolant being more than 300 degrees lower than the boiling point. At the same time, the inherent safety of the reactor is high, and non-energy systems can be used to remove the residual heat of the reactor during an accident.

A complete fast reactor nuclear energy system consists of fast reactor power plants, fast reactor fuel manufacturing plants, fast reactor spent fuel reprocessing facilities, and other parts.

By placing the fast reactor, fuel recycling items (including spent fuel reprocessing and new fuel manufacturing), and other supporting items at the same site, an integrated nuclear energy system with self-sustaining fuel circulation and rapid circulation within the plant will be formed.

According to calculations by the China Nuclear Energy Industry Association, by 2060, China's nuclear power installed capacity needs to reach 400 million kilowatts.

"Taking both safety and uranium supply into account, continuing to build pressurized water reactors at an installed capacity of 200 million kilowatts and then transitioning to integrated fast reactors will be a feasible technological approach to achieving the goal of nearly 400 million kilowatts of total installed nuclear fission energy by 2060," Zhou stressed.

However, the construction of integrated fast reactors still faces a long and arduous road. Integrated fast reactors still need to break through key technologies such as advanced reactors, advanced fuels, and advanced reprocessing, requiring significant innovation in engineering and technology, he noted.