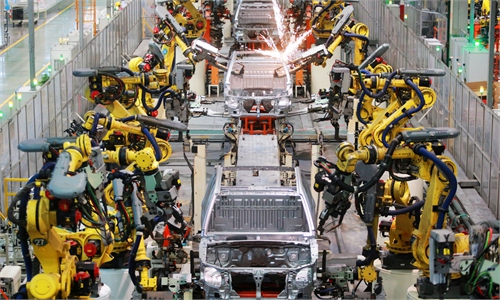

Industrial robots are operating on an intelligent production line in a smart manufacturing enterprise in Yangzhou, East China's Jiangsu Province. Photo: VCG

A growing number of Chinese provinces and cities, including economic powerhouses and innovation centers Guangdong and Shanghai, have taken proactive steps to promote deep integration of the manufacturing industry and cutting-edge tech such as cloud computing, big data, AI and robotics, to cultivate and develop new intelligent manufacturing clusters and smarter and more efficient factories.Shanghai on Tuesday released a plan to accelerate the integration of AI and manufacturing, setting ambitious targets for 2027.

The city aims to promote intelligent applications in 3,000 manufacturers, create 10 industry benchmark models and 100 benchmark smart products.

The plan also calls for the deployment of 100 cutting-edge application scenarios and build about 10 "AI+manufacturing" demonstration plants, as well as fostering a group of competitive service providers to accelerate the formation of an intelligent manufacturing ecosystem in Shanghai.

On August 11, Guangdong authorities issued new funding guidelines for AI and robotics innovations, specifying that national-level manufacturing innovation centers will receive fiscal support. Subsidies will cover up to 40 percent of the total amount of newly purchased research and development (R&D) equipment (including supporting software), with a maximum of 50 million yuan ($6.9 million) for each project.

The new policy will take effect on September 1, 2025, and remain valid until the end of 2027. Funded projects include establishing next-generation AI and advanced manufacturing centers, nurturing high-caliber innovative firms, launching flagship AI-for-industry-upgrade pilots, and supporting open-source communities and ecosystem hubs in the province, the guidelines revealed.

Beyond Shanghai and Guangdong, industry players across the nation have been actively supporting the digital transformation of assembly lines, and factories through using modern information technologies, aiming to help upgrade the manufacturing sector into intelligent industries.

For example, Jack Technology Co, a private enterprise based in East China's Zhejiang that started with household sewing equipment, has become one of the leaders in the global intelligent clothing equipment making through continuous technological innovation, patent accumulation, and international mergers and acquisitions.

As a "future factory" in Zhejiang, Jack Technology Co has been transformed from a traditional manufacturer to a global intelligent manufacturing giant, ranking first in the global sales volume of industrial sewing machines for 14 consecutive years. Its intelligent equipment has accumulated more than 3,200 valid patents and software copyrights, Xinhua News Agency reported.

Intelligent manufacturing creates opportunities for low-cost, green innovation, helps eliminate outdated equipment, and improves efficiency by reducing pollution, which is essential for environmental protection, Wang Peng, an associate research fellow at the Beijing Academy of Social Sciences, told Global Times on Tuesday.

Wang noted that the moves are expected to set up two major intelligent manufacturing hubs in the Yangtze River Delta and the Guangdong-Hong Kong-Macao Greater Bay Area, providing replicable and scalable models for smarter upgrade of China's manufacturing sector.

Data from the Ministry of Industry and Information Technology (MIIT) show that China is now home to more than 30,000 basic-level smart factories, 1,200 advanced-level and over 230 excellence-level smart factories. The 230 excellence-level factories cover 80 percent of manufacturing sectors. This achievement highlights the significant progress that has been made in reshaping the country's manufacturing landscape.

On average, they have shortened R&D cycles by 28.4 percent and boosted productivity by 22.3 percent.

According to Wang, the rapid transition is largely the result of the government's pro-growth policies. In a strategic move to build a number of high-level and smarter manufacturing factories, Chinese authorities decided in October, 2024 to roll out a four-tier cultivation system.

As China's manufacturing sector undergoes a fundamental transformation toward innovation, smart manufacturing has now become a new growth driver for Chinese economy, Wang said.

Data from the National Bureau of Statistics (NBS) showed that from January to July of this year, the value-added output of digital products manufacturing above the designated size rose by 9.5 percent, while output of intelligent equipment and electronic components and aerospace and aircraft equipment manufacturing industries rose by 12.8 percent and 8.6 percent, respectively.

Meanwhile, according to NBS, the rapid development of AI is now increasingly integrated with the real economy, with its application scenarios expanding. In July of this year, the added value of intelligent unmanned aerial vehicle manufacturing and intelligent automotive equipment manufacturing increased by 80.8 percent and 21 percent, respectively.

Global Times