Transforming traditional workshops

Chinese private companies become front-runners to embrace smarter manufacturing

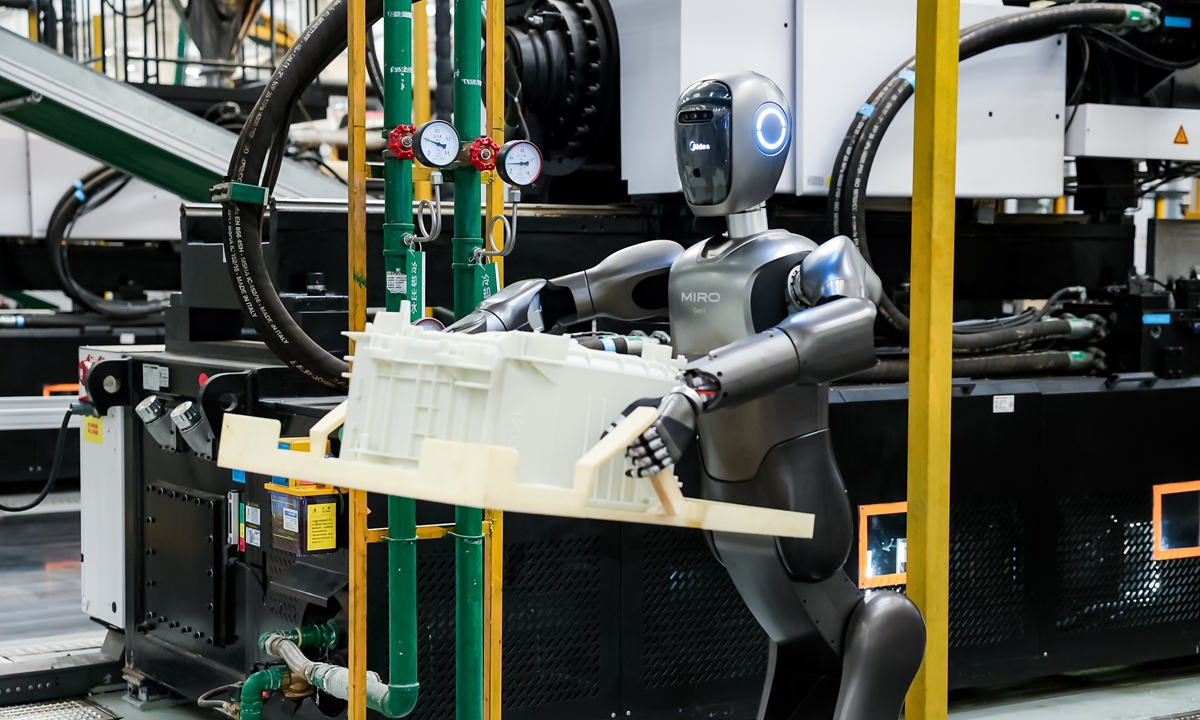

Humanoid robot Miro works at Midea's intelligent agent factory in Jingzhou, Central China's Hubei Province on August 26, 2025. Photo: Courtesy of Midea

In an injection molding workshop for Chinese home appliances manufacturer Midea, the company's first humanoid robot, Miro, is at work. Using dual-arm coordination with a single-arm load capacity of 3 kilograms, the robot can steadily carry a 9-kilogram washing machine tub and deliver it to the 3D quality inspection station.

After completing the delivery, this versatile "multi-task" robot turns to perform other assignments such as fire safety inspection and equipment monitoring.

The scene unfolds at Midea's washing machine factory in Jingzhou, Central China's Hubei Province, which has been certified by the World Record Certification (WRCA) as the world's first artificial intelligent (AI) agent factory.

Comprised of a factory "brain" and embodied intelligent terminals, it represents the next step in smart manufacturing. Miro first entered the factory as an "intern." Now, it has mastered its operational skills, marking a transformation from the laboratory to full deployment on the production line.

Midea is one vivid example of how China's private enterprises are embracing intelligent manufacturing. As the country steps up efforts to develop new quality productive forces to achieve high-quality growth, more private manufacturers are embracing the shift to smarter production.

These enterprises are integrating traditional industrial chains with artificial intelligence, humanoid robotics, and 5G communications, injecting new momentum into the country's high-quality economic development.

Intelligent transformation

This year, the All-China Federation of Industry and Commerce (ACFIC) carried out its 27th survey of large private enterprises in the country, with 6,379 companies reporting operating revenue above 1 billion yuan ($140.02 million). Among them, the top 500 companies by revenue make up the 2025 list of China's Top 500 Private Enterprises.

An ACFIC report noted that private enterprises are steadily transforming their development models. Among the Top 500, 66.4 percent are in manufacturing. Notably, 64.2 percent of them have formulated digital transformation plans.

Midea's Jingzhou washing machine factory is the company's third washing machine production base in China. Covering 42 hectares of land, it has a planned annual capacity of over 15 million units, making it the largest all-category washing machine mega-factory in the country. The factory integrates 5G, smart sensors and process control, AI, big data, and blockchain technology, serving as a testing ground for Midea's upgraded intelligent factory.

At the plant, Miro, the robot, works alongside 14 other AI agents, to back up 38 smart manufacturing scenarios.

In the fully automated molding process, 81 KUKA AMR robots are now deployed, which could detour around obstacles, form different formations on command from the factory brain, move empty racks, and monitor ground markers. The AI agent factory has achieved notable cost reductions and efficiency gains.

According to Lü Hongzhi, full-scenario intelligent collaboration has boosted efficiency by more than 50 percent across core business fields such as inspections, meetings, process documentation, and on-site problem-solving. Inspection efficiency alone has increased by 80 percent.

And, Chinese manufacturer of consumer electronics Goertek said that the company has been actively promoting intelligent manufacturing transformation, and has built the Goertek Production System, according to a statement from the company.

The intelligent manufacturing system integrates automation, machine vision, and AI across production processes, significantly enhancing efficiency and safety. As these technologies become part of daily operations, Goertek is training data analysts and AI specialists to strengthen employees' digital and learn management skills.

Demand-driven opportunities

On August 29, the National Development and Reform Commission (NDRC) held a press conference in Beijing to highlight the newly released "Opinions on Deeply Implementing the 'AI+' Initiative." Zhang Kailin, an official with NDRC, vowed to further unite state-owned and private enterprises, encouraging private companies to leverage their flexibility and innovation to emerge as "dark horses" in delivering technological breakthroughs.

The ACFIC report also noted that among the top 500 private enterprises in China, 64.2 percent have formulated digital transformation strategies, 60.2 percent have implemented digital management systems, and 66.8 percent have achieved cost reduction and efficiency gains through adopting digital transformation.

Analysts say that due to rising market demand and continuous government policy support, more private companies are moving toward intelligent manufacturing transformation, creating greater opportunities for robotics and AI firms.

On Wednesday, robotics firm UBTECH announced a 250-million yuan procurement contract with a leading Chinese enterprise for embodied humanoid robot products and solutions. The deal centers on its humanoid robot Walker S2, which features an autonomous hot-swappable battery system. Deliveries are set to begin later this year, marking the world's largest humanoid robot contract to date.

In July, UBTECH unveiled the Walker S2, the world's first humanoid robot with autonomous battery-swapping capability, enabling continuous 24/7 operation.

Currently, UBTECH has partnered with leading companies in new energy vehicles, 3C manufacturing, and smart logistics, including BYD, Geely, FAW-Volkswagen Qingdao, Audi FAW, BAIC New Energy, Foxconn, and SF Express.

Wang Peng, an associate research fellow at the Beijing Academy of Social Sciences, said that smart manufacturing is redefining competition in traditional industries, giving Chinese companies an edge, with intelligent manufacturing and advantages in cost, quality, and delivery speed.

Agile and market-sensitive, the private enterprises are the leading drivers of this smart transformation, Wang said, noting that these companies are deepening integration with next-generation technologies and expanding into strategic emerging industries to build new growth levers.