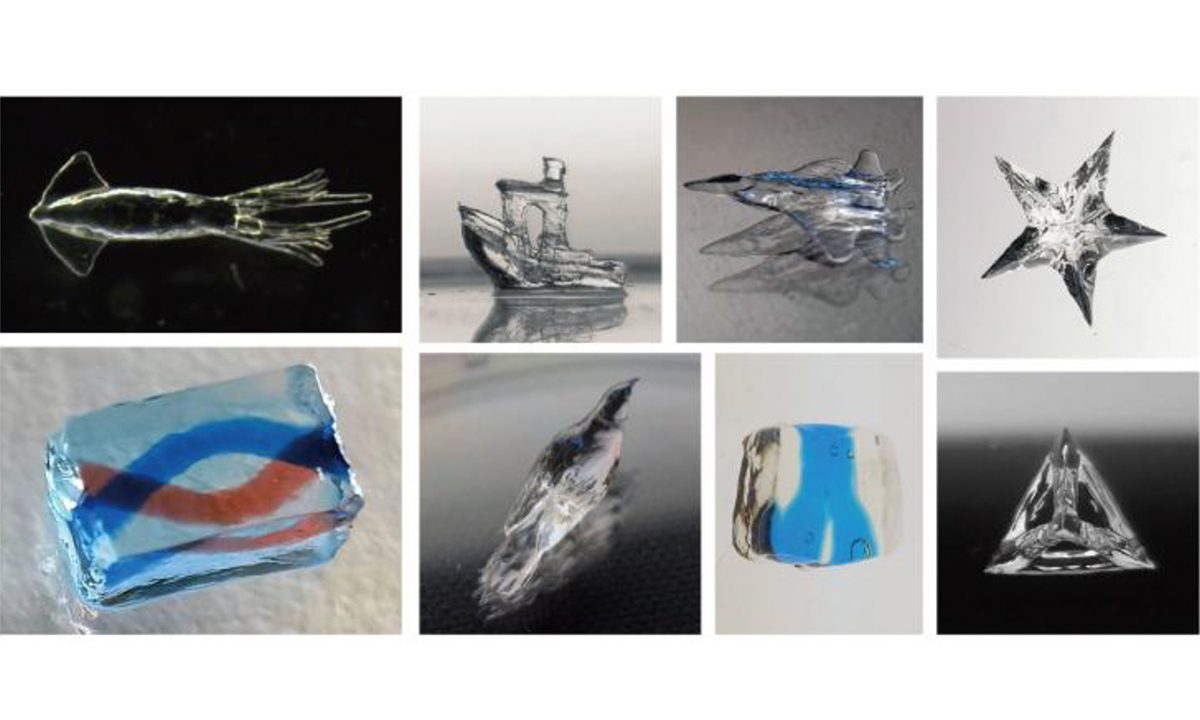

A showcase of complex 3D-printed objects Photo: Xinhua

Chinese scientists have developed a new type of 3D printing technology capable of fabricating complex millimeter-scale objects at high resolution in just 0.6 seconds – setting a new speed record, Xinhua News Agency reported on Thursday.

The findings were published online in Nature on Thursday.

Advances in 3D printing are crucial to the development of frontier fields such as biomedicine, micro- and nanotechnologies, and advanced manufacturing. However, the technology has long been plagued by a speed-precision trade-off: While precise mechanical control guarantees accuracy, it comes at the cost of relatively low printing efficiency.

High-resolution 3D printing of millimeter-scale objects often takes tens of minutes or even hours to complete and can hardly meet the needs of scientific research and industrial production.

In addition, existing 3D printing technologies are also limited by factors such as container design and material viscosity.

Led by Dai Qionghai, an academician of the Chinese Academy of Engineering, the research team from the Laboratory of Imaging and Intelligent Technology at Tsinghua University drew on expertise in computational optics. They discovered that this approach can manipulate high-dimensional holographic light fields to form three-dimensional solid structures.

Experiments show that this technology can produce complex millimeter-scale structures in just 0.6 seconds, with feature sizes as small as 12 micrometers, and achieves a printing rate of up to 333 cubic millimeters per second.

This marks the fastest 3D printing speed reported to date, according to Wu Jiamin, an associate professor and member of the research team. Wu said that through an innovative optical system design, the digital incoherent synthesis of holographic light fields (DISH) technology overcomes the speed bottleneck of point-by-point or layer-by-layer scanning. It can accurately project complex 3D light intensity distributions in a short time, enabling rapid object fabrication.

Another advantage of this technology is its minimal container requirements. It requires only a single optical plane and no precise movement of the container during printing.

This advantage significantly broadens potential applications, particularly allowing printing materials to be placed directly inside ordinary fluid channels, enabling batch and continuous printing in fluid environments.

According to Dai, the DISH technology provides a new solution for advancing related technologies in related fields. For example, in engineering and manufacturing, the technology could be used to mass-produce miniature components such as photonic computing components and smartphone camera modules, as well as parts with sharp angles and complex curved surfaces. Future applications may include flexible electronics, micro-robots and high-resolution tissue models.

Global Times