Sinovac Beijing vaccine production facility works overtime to supply global inoculation

Staff members seal the vaccines into plastic packaging. Photo: Li Hao/GT

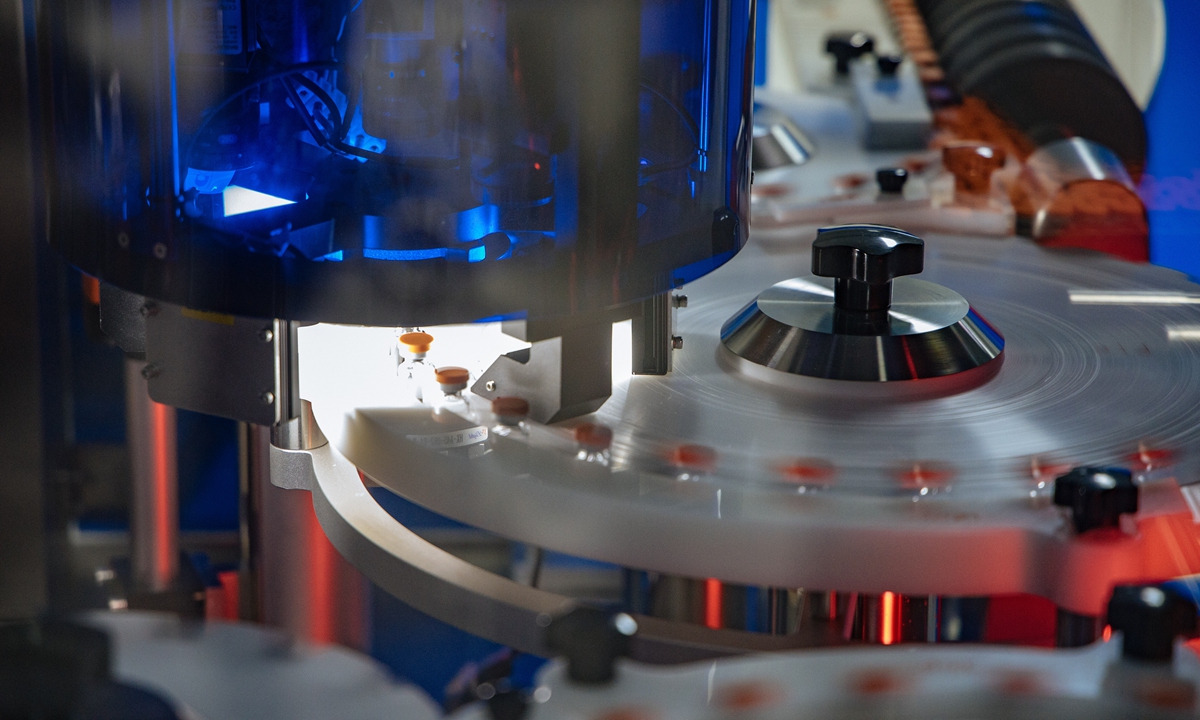

The Global Times reporters on Sunday visited the COVID-19 vaccine Beijing manufacturing plant of leading Chinese vaccine producer Sinovac to see how vaccines go through a complex packaging process - from vaccine bulk grouting to packaging - before they are shipped to vaccination sites around the world.

The vaccine production follows a strict and professional protocol. First, the Vero cells of the coronavirus will be transferred to a bacterial jar through a fully-sealed pipe so the virus can multiply in the jar. There will then be a transfer to a tailored medical jar for virus inactivation lasting two or three days. Those two steps will be carried out in the bio-safety level P3 bio-pharmaceutical production workshop.

After various tests, the vaccine pulp developed from the inactivated virus will be delivered to the production line for packaging with a sterile bottle and rubber plug. Before packaging, each vaccine is labeled and a batch number is tagged to trace the producer and status of transit.

The entire production line involves hundreds of testing items, covering key indicators of safety and effectiveness, the Global Times learnt from Sinovac.

The vaccine is stored in cold storage at a temperature of two to eight degrees Celsius. But thermal stability tests have shown the vaccine can be effective for injection within 42 days at 25 degrees and 21 days at 37 degrees.

For partner countries with independent vaccine packaging capabilities, Sinovac usually offers the vaccine bulk to the other countries such as Brazil and Indonesia upon mutual agreement.

COVID-19 vaccines. Photo: Li Hao/GT

Staff inspect the sterile needles and syringe bottles for the COVID-19 vaccine. Photo: Li Hao/GT

Vaccines are stored in a refrigerated warehouse before being shipped out. Photo: Li Hao/GT

A staff member shows finished vaccines filled in the vial. Photo: Li Hao/GT

The production chain uses digital technology to strictly monitor every step of production and packaging.