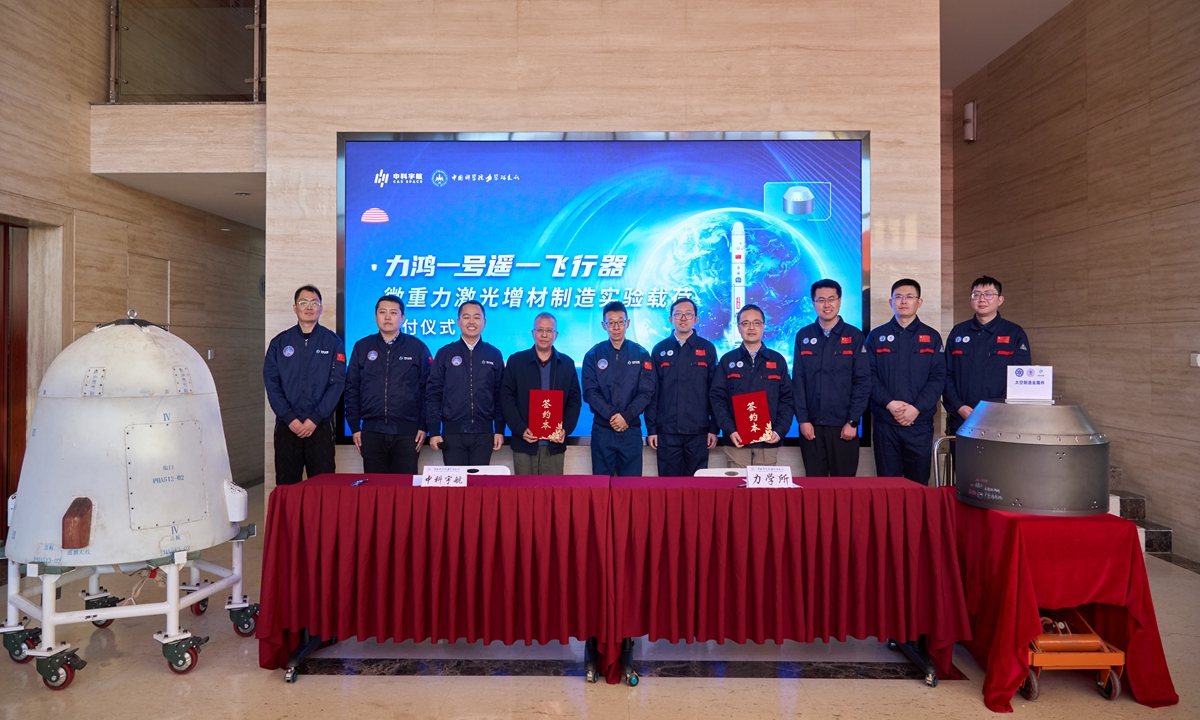

Photo: Courtesy of CAS Space

Chinese scientists have successfully completed country's first space-based laser wire-fed metal additive manufacturing experiment under microgravity conditions, conducting the work during a suborbital flight and achieving a major breakthrough, Chinese Academy of Sciences' (CAS) Institute of Mechanics announced on its website on Thursday.

The mission marks the official transition of China's space-based metal manufacturing technology from the "ground-based verification" to "in-space engineering verification," the institute said.

A microgravity laser additive manufacturing recoverable scientific experiment payload, developed by the Institute, was recently launched aboard the "PH-1" Yao-1 rocket developed by Chinese commercial aerospace company CAS Space, into a suborbital trajectory.

The rocket can bring the payload to a height of 120 kilometers above sea level and create a high-quality microgravity environment for more than 300 seconds.

The experiment has achieved key technological breakthroughs, including the formation and control of metal additive manufacturing under microgravity conditions, whole-process closed-loop monitoring and adjustment, as well highly reliable coordination between the payload and the rocket.

After the experiment, the payload capsule landed smoothly via a parachute system and was successfully recovered. Metal components produced via space-based additive manufacturing, complete experimental datasets, and performance parameters of the formed parts were successfully obtained by scientists.

Space-based metal additive manufacturing, or space-based metal 3D printing, is regarded as a key enabling technology for future space missions, according to the institute.

This technology enables on-orbit rapid manufacturing and autonomous repair of spacecraft components, drastically reducing reliance on ground supply and enhancing mission resilience and sustainability for deep-space exploration, long-term space station operation, and lunar base construction.

According to the institute, the research team has progressively established a fundamental theoretical framework and process database for space-based metal manufacturing through experimental systems, including microgravity drop towers, parabolic flight aircraft, suborbital rockets, and on-orbit platforms.

In the future, the PH-1 recoverable payload capsule will be upgraded into an orbital-level space manufacturing spacecraft with a maximum on-orbit duration of no less than one year and reusability of no fewer than 10 missions, per the statement.

It will be designed to meet the high-precision requirements of in-orbit manufacturing, supporting China's endeavors in on-orbit production as well as cutting-edge scientific experiments in fields such as microgravity physics, space life sciences and space materials science, the institute said.