Taikonauts verify adaptability and motion safety of homegrown pipeline inspection robot in China Space Station, marking a world first: CMSA report

Taikonauts carry out test and verification of the space station pipeline inspection robot in China Space Station. Photo: Courtesy of the China Manned Space Agency

China Manned Space Agency (CMSA) on Thursday released the official report detailing progress made in scientific research and applications related to the China Space Station in 2025. The report disclosed that for the first time internationally, an in-orbit test of a space station pipeline inspection robot was conducted in the China Space Station, verifying the robot's adaptability to the pipeline environment and the safety of its variable-stiffness motion.The space station pipeline inspection robot, according to the report CMSA provided to the Global Times on Thursday, is designed for regular patrol and inspection operations in complex pipelines under microgravity environments. In-orbit technical verification over the robot was conducted focusing on two key aspects, namely the robot's autonomous adaptation to complex pipelines in microgravity and the safety of its motion, per the report.

The robot was designed by the Institute of Intelligent Robotics, School of Mechatronical Engineering, Beijing Institute of Technology and the Department of Overall Spacecraft Design, Beijing Institute of Spacecraft System Engineering.

Drawing inspiration from the movement mechanism of echinoderm tube feet - which remain contracted within the body when stationary and extend outward during motion - researchers proposed a bionic variable-stiffness design concept: "autonomous extension, force-induced contraction, and passive softening without power."

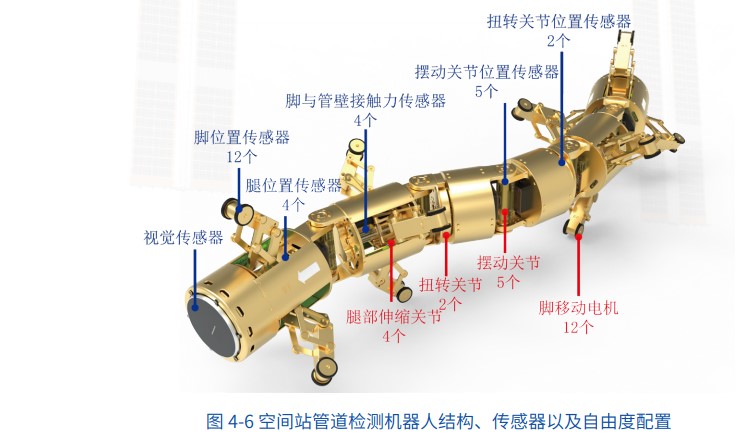

A leg mechanism combining active and passive scissor-type telescopic structures was designed, enabling the robot to adapt to the complex pipelines of the space station while ensuring the safety of the pipelines themselves, according to the CMSA.

An illustration of the pipeline inspection robot Photo: CMSA

A multi-task whole-body coordinated motion control algorithm tailored to the complex pipeline scenarios of the space station was developed, which utilizes information from whole-body sensors to calculate the pipeline robot's posture and position, and generates motion strategies.While prioritizing pipeline safety, it adjusts the position, velocity, and force output of all joints across the body, enabling the robot to move safely and smoothly inside the pipeline.

In-orbit tests of motion capability and mechanism adaptability were conducted, verifying the robot's autonomous motion technology and the safety of its passive compliant mechanism.

This in-orbit test of the pipeline inspection robot marks the first in-cabin special operations robot trial conducted on China's space station, according to the CMSA report.

It verified key technologies, including the design of a large variable-diameter pipeline robot capable of adapting to various complex pipelines and multi-level coordinated whole-body motion control.

The test also confirmed the robot's autonomous adaptive motion capability and safety in the complex pipeline environment of the space station, accumulating valuable experience for its practical application in space station pipelines.

In the future, the operational functions of the pipeline robot will be further enhanced to better serve the operation of China Space Station. It is also expected to be extended to applications in ground-based water, oil, and natural gas pipelines, as well as pipelines in polar scientific expedition stations.